PATH: HOME, GLOSSARY, WEBSITE INDEX, WEBSITE CONTENTS » ∨

∧ BOAT BUILDING & REPAIR » Boat Equipment » Propulsion Machinery » Engines »

∧ DO-IT-YOURSELF » DIY Boat Building & Repair, DIY Boat Inspections, DIY Schools & Classes »

∧ MEDIA w/Creator Directory » Product Documentation, Books, Magazines, Videos, Websites »

PAGE CONTENTS: (click ⇒ to go to each section on this page)

⇒ Topic Treatment: Introduction, Overview, Background, Details, Directories,+.

⇒ ^ Related Resources: EAB Topics w/Directories, Vendors, Products: Media: Books, Websites,+.

⇒ Visit EAB's FEATURED ARTICLES Home Page to preview the vast scope of our website.

⇒ This Month's Top 20 Most Popular Articles on our EAB website.

⇒ Layout of the EverythingAboutBoats.org Website's Pages: Page Types, Contents, Topics,+.

⇒ What our nonprofit Anchors Aweigh Academy and its EAB website have accomplished.

⇒ Members must SIGN IN to gain access to Members Only areas of this website.

⇒ Become an Academy Member and gain access to additional pages and programs!

⇒ Comments: Submit To ⇒ Comments♥EverythingAboutBoats.org (Replace "♥" with "@").

THIS ARTICLE IS STILL EVOLVING!

The page may contain rough drafts that include raw source materials.

This article describes the arrangement of mechanical components in Internal combustion reciprocating piston engines. For External combustion engines including steam engines and internal combustion engines other then reciprocating piston engines such as rotary engines and gas turbines, see our Propulsion Machinery page.

Modern internal combustion reciprocating piston engines are most often fueled by Gasoline (commonly called just “Gas”), or Diesel. But they can also be fueled by Natural Gas (NG), Compressed Natural Gas (CNG), Liquid Petroleum Gas (LPG) such as Propane and Butane, or heavy fuels such as Bunker Fuel. They may be spark ignited like gasoline engines or compression Ignited like Diesel engines. While they share very similar basic mechanical components including pistons, connecting rods, crankshafts, valves, etc., they also have their differences, especially in their fuel delivery systems, which may be carbureted or fuel injected.

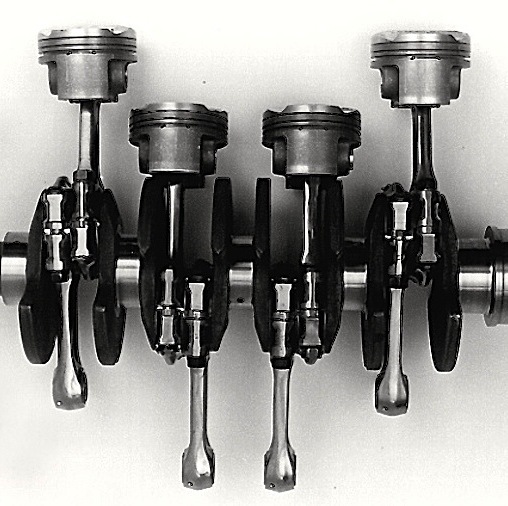

Pistons, Connecting Rods & Crankshafts

+

How Piston Skirt Length Affects Engine Service Life.

+

Compression Ratios

petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas), Spark Ignition.

Diesel Engine, Diesel Fuel, Compression Ignition.

PIX

Blow-by (w/id)

Slip-Bearings vs Roller Bearings.

PIX

Piston Configurations

+

Single Cylinder

PIX

+

Inline

PIX

+

V

PIX

+

+

PIX

+

Radial vs Rotary Radial

PIX

+

Opposed-Piston

PIX

+

Deltec

+

Crosshead engine.

+

Engine Block

+

Deck

PIX

+

Head Gasket

PIX

+

Cylinder Head

PIX

+

2-Stroke Cycle vs 4-Stroke Cycle. Others.

Four-Stroke Engine, Otto Engine, Otto Cycle, Atmospheric engine.

PIX

+

+

Types of cylinders: Wet Liners, Dry Liners & Parent Bore. Repair Sleeves.

Valves vs Ports. Poppet Valves vs Sliding Sleeve Valves

PIX

+

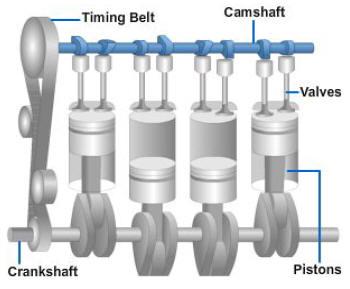

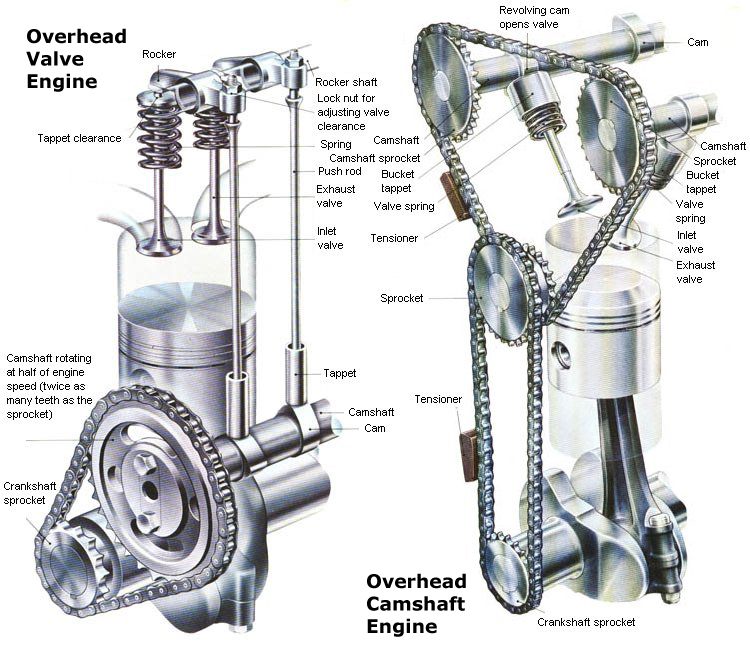

Over-Head Cam (OHC) vs Overhead Valve (OHV) engines

Over-Head Cam (OHC).

Also written as an “Overhead Cam” engine.

A camshaft can be driven by a belt as illustrated above or by a timing chain,

a timing gear set, or a perpendicular shaft with bevel gears as shown below.

Below are chain driven camshafts.

The illustration on the left shows an “Overhead Valve” (OHV) engine with a chain driven cam

in the cylinder block with tappets (sometimes called “lofters”), push rods and rocker arms.

The illustration on the right shows a chain driven “Dual-Overhead Cam” (DOHC)

which is sometimes called a “Twin-Overhead Cam”.

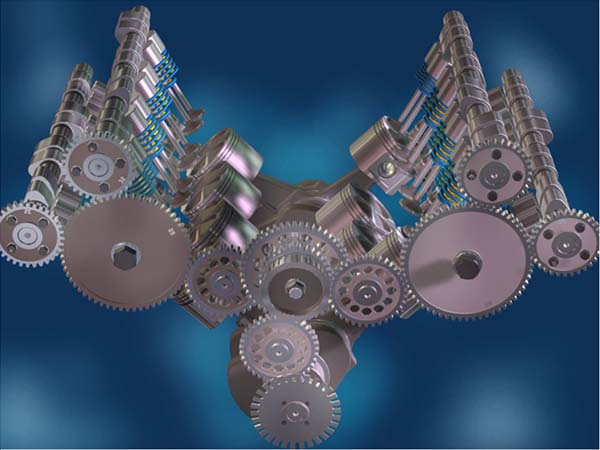

Below are the gear driven cams of a Cosworth V8.

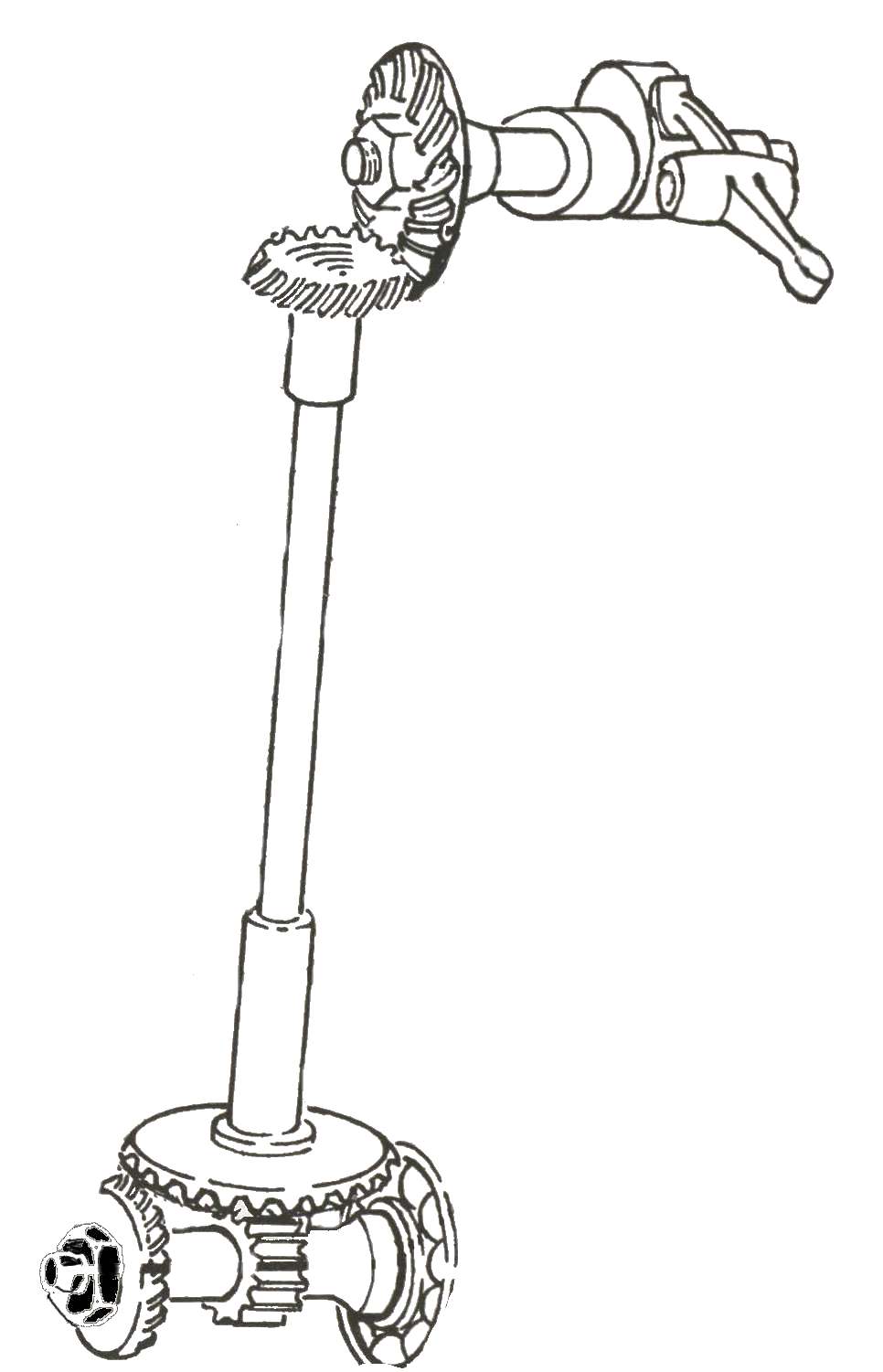

Below is a cam driven by a perpendicular shaft with bevel gears.

The top bevel gear is attached to the camshaft and is driven by the perpendicular shaft.

The bottom bevel gear is attached to the crankshaft and drives the perpendicular shaft.

This type of camshaft drive was used by the Bearcat 4-Stroke Cycle outboard motor.

Valve Lifter Basics and Beyond

By Larry Carley

Sep 1, 2017

Valve lifters play a key role in the valvetrain of pushrod engines. They go all the way back to the earliest days of the internal combustion engine. The earliest engines did not have pushrods or rocker arms. They were a “flathead” design with the valves in the block. The lifters (also called “tappets” because of the clattering noise they produced) rode on the cam lobes in the block and actuated the valves directly.

Valve lifters play a key role in the valvetrain of pushrod engines. They go all the way back to the earliest days of the internal combustion engine. The earliest engines did not have pushrods or rocker arms. They were a “flathead” design with the valves in the block. The lifters (also called “tappets” because of the clattering noise they produced) rode on the cam lobes in the block and actuated the valves directly. It was a simple design but not the best configuration for breathing efficiency or horsepower.

Relocating the valves to the cylinder head was a major step forward in “overhead valve” (OHV) engines because it allowed the engine to breathe more efficiently and develop more horsepower from the same displacement. The overhead valve design added complexity to the valvetrain because it required the addition of pushrods and rocker arms. The lifters also had to route oil up through the pushrods to lubricate the upper valvetrain components.

With “overhead cam” (OHC) engines, the camshafts are in the cylinder head(s) and actuate the valves directly or via cam followers, so there are no lifters. However, most modern OHC engines do have some type of hydraulic valve lash adjusters. The adjuster may be mounted in the head and serve as a fulcrum point to maintain zero lash between the cam follower and valve, or located inside a bucket that fits over the top of the valve, or a “mini-adjuster” mounted in the end of the rocker arm.

The Lifter’s Role In the Valvetrain

The basic function of a valve lifter is pretty simple. It sits on the camshaft and transfers the motions of the cam lobe up through the pushrods and rockers to open and close the valves. The size and shape of the cam lobe under the lifter (multiplied by the ratio of the rocker arms) determines valve lift and duration. As such, the lifter just follows the motions of the cam. But it does play a role in valvetrain lash (clearance) and noise.

In “solid lifter” pushrod engines, the lifter is just a hollow bucket. It has a hard faced bottom that rides on the cam, and a cup on top that supports the lower end of the pushrod. The lifter has an inlet hole in the side so pressurized oil can fill the lifter body, and an outlet hole in the center of the pushrod cup so oil can flow up through the pushrod to lubricate the upper valvetrain components.

With “flat tappet” pushrod engines, the bottoms of the lifters appear to be flat. But actually on most applications the bottoms of the lifters are slightly convex. The center is about .001 to .002˝ higher than the edge. Also, the lobes on flat tappet cams are not perfectly flat but have a slight taper (.0007 to .002˝) to one side. In addition, the centerline of the lifters are offset slightly with respect to the cam lobes. This makes the lifters rotate as the cam turns, which helps to reduce friction and wear.

The area of contact between the lifters and cam lobes is the highest loaded surface inside an engine, with as much as 200,000 to 300,000 PSI at the point of contact depending on valve spring pressure! Consequently, it is critical that both components have the correct geometry (both convex and taper), that both surfaces have adequate hardness to resist premature wear and failure, and that the point of contact receives good lubrication with a motor oil that contains sufficient levels of high pressure anti-wear additive (such as ZDDP).

Lubrication has been a problem in recent years because the amount of ZDDP in motor oil has been significantly reduced to prolong the life of catalytic converters. The zinc and phosphorus in ZDDP anti-wear additive will contaminate the catalyst if an engine is burning oil due to worn valve guides, seals and/or piston rings. Reducing ZDDP to less than 600 ppm has not created a problem for most late model engines because they have low friction roller lifters or overhead cam followers. But in older engines with flat tappet cams, using a low ZDDP motor oil may not provide adequate wear protection for the cam and lifters – especially if stiffer valve springs are installed. The work around is to use a break-in oil that contains higher levels of ZDDP, and then refill the crankcase with a specially formulated “street performance” or “racing” motor oil that contains extra ZDDP. A ZDDP additive can also be used to fortify low ZDDP conventional and synthetic motor oils.

Aftermarket cam suppliers have also upped their game by increasing the surface hardness of their flat tappet cams to make them more wear resistant with today’s motor oils. Some suppliers offer lifters that have a small pinhole burned through the bottom center of the lifter body to direct oil right to the cam lobe. Another supplier grinds several small flats only a few thousandths of an inch deep down the sides of their lifters so more oil can flow down onto the cam.

Roller Lifters

A big improvement came about with the invention of roller lifters. By placing a small wheel on the bottom of the lifter, friction between the cam and lifter is greatly reduced. That’s why all modern pushrod engines have roller lifters. Roller lifter also allow the use of more radical cam lobe profiles with faster opening and closing ramps that allow more total valve opening for a given lift and duration. That’s why roller cams are the hot setup for racing.

Mounting a wheel on the bottom of the lifter also changes the dynamics between the lifter and cam. A roller lifter has to be held in fixed alignment with the cam so the wheel will roll smoothly on the lobe, so you don’t want the lifter to rotate or twist. This requires the addition of a linkage bar between adjacent lifters to keep them straight, or machining the lifter body and lifter bores with a flat to prevent them from twisting.

One of the differences between a roller cam and a flat tappet cam is that the lobes on a roller cam are truly flat whereas those on a flat tappet cam have a slight taper. If the wrong type of cam or lifters are used together (flat tappet cam with roller lifters, or a roller cam with flat tappet lifters), the mismatch will cause bad things to quickly happen.

Something else that should never be done when rebuilding an engine is to install a new cam with used lifters. The cam and lifters develop a specific wear pattern to each other as they seat in. If a high mileage cam is worn, or one or more lifters show concave wear on the bottom, the cam and lifters all need to be replaced.

If the original cam and lifters are still in good condition and are being reused, make sure all of the lifters are reinstalled in their original holes (same location as before). However, if the original cam is worn and needs to be replaced, replace the lifters too. Don’t ruin the new or reground cam by reusing worn lifters.

The only exception to this rule is with roller cams. Because the cam lobes are flat and the lifters have rollers rather than a convex surface, a new roller cam can be installed with used roller lifters provided all of the lifters are in good condition with no damage, pitting or cracking.

Hydraulic Lifters

Hydraulic lifters were first developed back in the 1930s and became common in production engines in the 1950s. Hydraulic lifters eliminate the clatter produced by solid lifters because the valvetrain runs with zero lash (clearance). Solid lifters require a small air gap between the tips of the rocker arms and the tops of the valve stems to compensate for thermal expansion in the engine as it heats up. Lash adjustment is critical because too much clearance makes the valves noisy and reduces valve lift, duration and performance. Too little clearance can also create problems because it causes the valves to open sooner and close later, reducing heat dissipation through the valve seats when the valves are closed. This can make some valves (especially exhaust valves) run too hot and fail. If the lash is way too tight and closes up entirely, it may hold the valve open causing a loss of compression and possibly contact between the valve and piston.

Solid lifters require regular valve lash adjustments to compensate for wear in the valvetrain. With racing engines, valve lash adjustments may also be required to fine tune the engine for prevailing weather and track conditions. Changing valve lash has the same effect as changing valve lift and duration. Less lash increases lift and duration for more high end power, while opening up the lash adjustment decreases lift and duration to improve low RPM torque and throttle response.

Hydraulic lifters eliminate the clatter and the need for periodic adjustments by maintaining zero clearance when the engine is running. They do this by using oil pressure against a spring-loaded plunger inside the lifter body. Oil fills the cavity under the plunger when the valve is closed. This pushes the plunger up to take the slack out of the valvetrain and hold it tight. A one-way check valve inside the lifter holds the pressure inside the lifter as the valve opens. Since oil is incompressible, the oil trapped under the plunger prevents the plunger from compressing and the lifter act like a solid lifter to push the valve open.

Hydraulic lifters are also kinder on valvetrain components than solid lifters because zero valve lash reduces the hammering effect that occurs when the valves slam shut at higher engine speeds. There’s no air gap to fill so the valve simply follows the cam lobe as it closes for a more gentle landing. This also reduces noise and helps extend the life of the valvetrain components.

Under normal driving conditions, there’s no danger of the valves being pushed off their seats or not fully closing when they seat because the valve springs exert more pressure on the valvetrain than oil pressure inside the lifters. But at high engine speeds (say over 6,000 to 6,500 RPM), hydraulic lifters experience some limitations.

At high speed, hydraulic lifters may “pump up” and hold the valves open causing the valves to float. This can happen if the valve springs are not strong enough to maintain normal valve control, and the lifters try to take up the slack that really isn’t there. This overextends the plunger and prevents the valve from closing all the way. The same thing can happen if the oil inside the lifter does not bleed down quickly enough between cycles to maintain normal valve lash.

Hydraulic lifters can also “pump down” or collapse” at high RPM if they are leaking too much oil pressure internally due to sloppy assembly tolerances. This creates too much lash in the valvetrain, which results in noise and loss of power.

Hydraulic lifters are precision fit assemblies. The plunger is closely matched to the housing to provide minimal clearance so the leakdown rate is not too great or too small. That’s why you should never intermix the internal parts when you are cleaning and rebuilding a set of hydraulic lifters. Do each lifter individually so the original assembly tolerances are maintained.

One of the key differences between stock production hydraulic lifters and aftermarket performance lifters is that the latter usually have tighter internal tolerances for better oil control. Many performance hydraulic lifters also have better valving that allows them to handle more RPMs than their stock counterparts. A good set of aftermarket performance hydraulic lifters will typically allow an engine to rev 1,000 RPM higher than with stock hydraulic lifters. Some can handle even more RPMs. Even so, most hydraulic lifters can’t match the performance and reliability of solid lifters over 8,000 RPM. That’s why high revving engines in NASCAR, drag cars and circle track cars still use solid lifters.

Hydraulic Adjustments

Hydraulic lifters still need to be adjusted when they are initially installed so the plunger will operate in its mid-range of travel. If the plunger bottoms out, it may prevent the valve from closing causing a rough running engine and possible valve-to-piston contact. A plunger that is over extended and near its upper range of travel may not be able to maintain zero lash as engine temperature changes. This can increase engine noise, and it may even cause the plunger to hammer against the snap ring causing it to fail.

A hydraulic lifter plunger may also become over extended if an engine has sticking valves or excessive wear in the valvetrain. It can only take up so much slack before it runs out of adjustment.

Something else to keep in mind if you are replacing a set of hydraulic lifters is to make certain the plunger height in the replacement lifters is the same as the old lifters. A difference in plunger height will require longer or shorter pushrods to compensate.

New Lifter Designs

The ongoing quest to squeeze more fuel efficiency out of today’s engines has lead to the development of various “displacement on demand”, “variable displacement” or “cylinder deactivation” technologies on some engines. Basically, the idea is to deactivate up to half of the engine’s cylinders when it is under light load to conserve fuel. Switching off the fuel injectors to kill certain cylinders saves fuel. But if the valves are still opening and closing the engine is wasting energy pumping air through the dead cylinders. The valves also have to be deactivated at the same time to maximize the energy savings.

Deactivating the valves traps air in the dead cylinders. This creates an “air spring” effect that returns almost as much energy on the piston downstroke as is put in during the compression upstroke. The engine squeezes the air during the compression stroke, and the air pushes back as it expands during the downstroke.

There are various ways to deactivate cylinders, including cams that have different lobes for each cylinder, changing the position of the rockers or using hydraulic lifters that can collapse on command to eliminate valve lift. A variable position valve lifter can operate with normal plunger height or reduced plunger height. This requires a secondary oil supply hole and valving to change the position of the plunger inside the lifter.

The powertrain control module (PCM) regulates the oil pressure to the lifters via solenoid valves. With multiple cylinder deactivation, several solenoids may be used to control oil flow to various lifter pairs. Cylinder deactivation adds more complexity to the valvetrain and increases the chance of something going wrong and causing a loss of power if cylinders remain deactivated when they should be producing power. Problems with engine sensors (notably MAP, airflow and throttle position sensors), the oil flow control solenoids, engine oil pressure (if the engine is also equipped with a variable displacement oil pump), the PCM or wiring faults may all affect the normal operation of such a system.

Assembly Tips

When installing a new or reground cam and lifters, use a high pressure cam lube rather than motor oil or general purpose assembly lube to coat the cam lobes and bottoms of the lifters, and use a break-in oil that contains extra ZDDP. The high pressure lube is necessary to protect the cam and lifters following the initial start up and break-in process.

A new cam and lifters can be ruined if not broken in properly. Most require keeping the engine RPMs between 1,500 to 2,000 RPM for 20 minutes. Don’t let the engine idle and don’t over rev it either. The cam and lifters need plenty of lubrication during this period, and minimal stress as the lifters and lobes get to know each other. Final valvetrain adjustments and engine tuning can be done after the initial cam break-in period is over.

Roller cams are more forgiving than flat tappet cams as far as break-in is concerned because there is much less friction. Even so, the engine RPMs need to be kept about 1500 to 2000 RPMs following the initial startup for several minutes to make sure everything is compatible and is getting sufficient lubrication.

Hydraulic lifters will normally make some noise when an engine is initially fired up, but should soon quiet down as oil fill the lifters and the lifters expand to tighten up the slop in the valvetrain. Some experts say hydraulic lifters should be presoaked in oil and bled prior to installing them. Others say this isn’t necessary and actually increases the risk of the lifters holding the valves too far open.

The normal procedure for adjusting a set of hydraulic lifters is to rotate the cam so each pair of lifters is at their lowest position on the base circle of the cam. This is done by rotating the crank so that cylinder is at Top Dead Center on its compression stroke with both valves fully closed. The rockers are then adjusted to zero lash and then given an additional 1/2 to 3/4 turn to push the plungers inside the lifters down to their midrange position. The procedure is then repeated for each cylinder until all the lifters have been preset. If the lifters are prefilled with oil, they may not push down when the rockers are given the additional twist causing the valves to lift off their seats instead.

From enginebuildermag.com

Flat-Tappet vs Roller Tappet

+

Flat-Tappet Camshaft Failures.

Camshaft & Lifter Failures

ΞPIXΞ

Flat-Tappet Camshaft Failures have been a growing problem in marine engines.

ΞPIXΞ

ΞCaptionΞ.

ΞTopic_TreatmentΞ

+

Describe Valve trains? Complex.

From ΞSourceΞ.

Why Do Camshafts Fail?

By Engine Builder

Nov 24, 2009

Here’s a list of common mistakes we have determined to cause camshaft failure:

1. Lobe Wear

Use only the manufacturer recommended lubricant, which is generally included with the cam. This lubricant must be applied to every cam lobe surface, and to the bottom of every lifter face of all flat tappet cams. Roller tappet cams only require engine oil to be applied to the lifters and cam. Also, apply the lubricant to the distributor drive gears on the cam and distributor.

2. Incorrect Break-In Procedure

After the correct break-in lubricant is applied to the cam and lifters, fill the crankcase with fresh, non-synthetic oil. Prime the oil system with a priming tool and an electric drill so that all oil passages and the oil filter are full. Preset the ignition timing and prime the fuel system. Fill the cooling system. Start the engine. The engine should start quickly and run between 1,500 and 3,000 rpm.

If the engine will not start, don’t continue to crank for long periods as this can shorten the life of the cam. Check for the cause of the problem and correct it. The engine should start quickly and be run between 1,500 to 3,000 rpm. Vary the rpm up and down in this rpm range for 20 minutes. During break-in, verify that the pushrods are rotating, as this will show that the lifters are also rotating. If the lifters don’t rotate, the cam lobe and lifter will fail. Sometimes you may need to help spin the pushrod to start the rotation process.

3. Always Use New Lifters With A Flat Tappet Cam

If you are removing a good used flat tappet cam and lifters and are planning to use them again in the same (or another) engine, you must keep the lifters in the order they were removed from the cam they were on. Lifters “mate” to their specific lobes and can’t be changed. If the used lifters get mixed up, discard them, install a new set of lifters, and break in the cam in again. You can use new lifters on a good used cam, but never use used lifters on a new cam.

4. Incorrect Valve Spring Pressure

Recommended valve spring seat pressure for most street-type flat tappet cams is between 85-105 lbs. More radical street and race applications may use valve spring seat pressure between 105-130 lbs. For street hydraulic roller cams, seat pressure should range from 105-140 lbs. Mechanical street roller cams should not exceed 150 lbs. Race roller cams with high valve lift and spring pressure are not recommended for street use, because of a lack of oil splash onto the cam at low speed running. Springs must be assembled to the manufacturer’s recommended height. Never install springs without verifying the correct assembled height and pressures.

NOTE: Increased spring pressure from a spring change and/or increased valve lift can hinder lifter rotation during cam break-in. Decreasing spring pressure during break-in can be accomplished by using a shorter ratio rocker arm to lower the valve lift and/or removing the inner spring if dual springs are being used.

5. Mechanical Interference

A. Spring coil bind. This is when all of the coils of the spring contact each other before the valve fully lifts. Valve springs should be capable of traveling at least .060″ more than the valve lift of the cam from its assembled height.

B. Retainer to seal/valve guide boss interference. At least .060″ clearance is required between the bottom of the retainer and the seal or the top of the valve guide when the valve is at full lift.

C. Valve to piston interference. This occurs when a change in cam specs (lift, duration, or centerline) is enough to cause the valve and piston to contact. Also, increased valve size or surfacing the block and/or cylinder head may cause this problem. Minimum recommended clearances are .080″ intake and .100″ exhaust.

D. Rocker arm slot to stud interference. As you increase valve lift, the rocker arm swings farther on its axis. Therefore, the slot in the bottom of the rocker arm may run out of travel and the end of the slot will contact the stud and stop movement. The slot in the rocker arm must be able to travel at least .060″ more than the full lift of the valve.

6. Distributor Gear Wear

The main cause for distributor gear wear is the use of high volume or high pressure oil pumps. If these types of oil pumps are used, reduced cam and distributor gear life will result. However, you can increase the gear life by adding more oil flow over the gear area to help cool off the point of contact.

7. Camshaft End Play

Some engines use a thrust plate to control the forward and backward movement of the camshaft in the block. The recommended amount of end play on these types of engines is between .003″ to .008″. Many factors can cause end play to change. When installing a new cam, timing gears, or thrust plates, be sure to verify end play after the cam bolts are torqued to factory specs. If the end play is excessive, it will cause the cam to move back in the block, causing the side of the lobe to contact an adjacent lifter.

8. Broken Dowel Pins Or Keys

The dowel pin or Woodruff key does not drive the cam; the torque of the timing gear bolts against the front of the cam does. Reasons for the dowel pin or key failing are: Bolts not being torqued to correct specs, incorrect bolts of a lower grade stretching and losing torque, not using the correct hardened washer which may distort and cause torque of the bolt to change, LocTite not being used, or some interference with the cam, lifters, or connecting rods causing the cam to stop rotation.

9. Broken Cam

A broken camshaft is usually caused by a connecting rod or other rotating part coming loose and striking it. Sometimes the cam will break after a short time of use because of a crack or fracture in the cam due to rough handling during shipping or improper handling prior to installation.

Causes and Contributing Factors of Camshaft & Lifter Failures

Manufacturing Flaws: Casting, Materials, Surface Treatment.

Higher engine RPMs:

More inertial force loads on cam lobes and lifters to open valve.

Stronger Valve Return Springs to overcome inertial force needed to close valves. Push rods, Rockers.

Rocker arm friction. GM+, Oil.

Engine Overheating: Cooked oil. Distemper.

+

+

Poor cam breakin.

Oil; Less zinc.

Engine Lubricants – Solving The Flat-Tappet Puzzle

How Lubricant Choices Contribute to Flat-Tappet Cam Failure

wp engine Words

Jul 1, 2008

Flat-tappet camshafts are commonplace in the motorsports scene. From NASCAR Sprint Cup Series to IMCA Mods, guys across the nation are running this venerable design. About ten years ago, these cams started failing for no apparent reason. Through quite a bit of hard work, the cam companies eventually got to the root of the problem…oil. Since then, it has been fairly well publicized and one would think with all the media coverage of the subject racers would have caught on. However, people are still experiencing problems with their flat-tappet cams so we decided to take a look at the solution.

Of course before delving into the solution, let’s take a look at the problem. All motor oils contain a variety of additives based on their intended use-high RPM, high mileage, low temperature, etc. Some have more, some have less. It all depends on the application. For years, one of those additives was Zinc Dialkyl Dithio Phosphate, or more commonly known as ZDDP. Originally developed in the ’30s, ZDDP is an anti-wear/anti-oxidant additive. It also offers up excellent anti-scuffing properties as well, making it a perfect protectant for engines running flat-tappet cams. It was a standard ingredient in motor oil all the way through the ’90s.

Unfortunately, the phosphorous in ZDDP plays havoc with catalytic convertors. The roller cam engines of today’s production cars don’t require the oil to have a big shot of ZDDP, so Detroit lobbied the oil companies to drop the ZDDP levels to preserve the cats and, subsequently, make it easier to achieve the government mandated 100,000 mile emissions warranty.

The problem was nobody in the oil companies said anything to the aftermarket. “I think from our standpoint they neglect to see an entire market that exists today,” says Comp Cams’ Scooter Brothers. “They saw it only through their eyes and figured everything has roller cams in it so it’s no big deal. Let’s just do it.”

These formulation changes had a huge effect on the aftermarket that rippled through the racing community, and Brothers had firsthand experience with it. “Many years ago I had the problem with the engines from Roush. We couldn’t even get an engine off the dyno without failing a cam,” says Brothers. “We kept beating ourselves up thinking we didn’t know how to make a cam anymore. We changed tapers, we changed lifters, we changed everything we knew how to change on the cam looking for the solution.”

Brothers sort of laughs about the incident now, but it was a lot of work back then.

“We went through all kinds of things throughout this process of trying to find out what was wrong, scribing a little line on the lifter bores to squirt a little oil down there, drilling a hole in the bottom of the lifter, putting a spray bar in there to spray oil directly on the cam. Well, that was when Roush was sponsored by Valvoline, and we found out that somebody in the Valvoline labs changed something in the oil. As it turned out, as long as we had the correct oil it was fine. You know we just didn’t have the right lubricant package in the oil.” Once Brothers and Roush got the manufacturer to put the ZDDP back in the oil, the problem went away.

In heavily loaded applications such as a race motor, an oil wedge between metal parts such as camshaft, rockers, etc., cannot be sustained. As a result, metal-to-metal contact will occur unless a sacrificial coating is formed (see chart A, p.48). ZDDP is a polar molecule, so it’s attracted to carbon steel surfaces where it reacts with heat, to create that sacrificial coating. The protective coating prevents metal-to-metal contact, which reduces friction and wear, and ultimately in a race motor prevents flat-tappet cam failure.

It’s simple enough. If you run a motor with a flat-tappet camshaft then you need to use the proper assembly lube, break-in oil and racing oil all the time. These lubricants should have enough ZDDP or other zinc additive to provide a sufficient buffer against cam lobe failure. Today’s race motors have higher engine speeds, higher spring loads, faster lifter acceleration and more. We’re using crankcase evacuation systems where there is negative pressure in the crankcase which is pulling all the oil away from the camshaft. All of these things add up to a tremendously harsh environment. If you aren’t using the right lubricant package you’re asking for trouble.

But be warned, you may have a buddy who has run standard engine oil in his flat-tappet motor and never experienced a problem. “There’s a chance that he’ll put it in and never have a problem,” says Brothers. “It’ll perform just fine, it’ll break in just fine and he’ll never have a problem. However, that all depends on where that engine falls in the performance spectrum and how lucky the guy is that day.”

The risk isn’t worth it, and there is absolutely no risk to using the proper oils. So, unless you like replacing expensive engine components, you should not be buying the motor oil for your race engine at Wal-Mart. But how do you know which oil is the best for your application? Ask. There are a number of manufacturers out there who produce and market oils and lubricants specifically for racecar applications, such as Brad Penn, Royal Purple, and Joe Gibbs Racing Oil. All of which have sufficient levels of ZDDP to ensure flat-tappet cam operation.

“Late in the ’90s we first began to see the problem,” says Lake Speed Jr. of Joe Gibbs Racing Oil. “With the reduction in phosphorous and zinc levels, we began to experience engine failures with our Cup series engines. Of course this was magnified by the fact we were trying to turn 9,000 rpms.” At the time the team had a sponsorship from an oil company making it relatively easy for them to find and solve the problem. Their sponsor custom blended an oil formula for them that solved their problem. “We needed a lube system that would allow us to assemble and break in the engine so that we knew what we had,” says Speed. Eventually that formulation provided the foundation for a whole business for Gibbs and now that race team sells the oil they use in their cars.

Like Gibbs, American Refining Company offers a range of lubricants under the Brad Penn brand that offer high ZDDP concentrations for racing applications. American Refining Company is the oldest continuous running refinery in the United States. In addition, they are the only refinery in the United States that processes 100 percent pure Pennsylvania crude oil, which provides a unique cut off of the fractional tower. Now, refining crude oil into gasoline, butane, and motor oil is a complicated process, but suffice to say the fractional tower is a key machine in the whole system. The “cut” is oil industry speak that refers to the base oil taken from the refining process. Once a base oil is in hand, refineries can then begin to add other additives to develop a product that delivers optimum lubrication for a particular application.

American Refining’s Dick Glady cautions that achieving the optimum lubrication for your race engine means balance. “The industry is attributing a lot of the problems with flat-tappet cams to the reduction of the zinc in the oil. That reduction upset the balance. Having a good balance of base oils and additives is the key in formulating a good race engine oil. For example, race engine oils need to have a range of 1,200 to 1,500 ppm (parts per million) of zinc. Our Brad Penn Grade 1 Racing Oils have 1,500 ppm zinc and 1,410 ppm phosphorus.”

But having those levels of zinc and phosphorous are only half of the equation. You also need to consider the base oils. Pennsylvania crude oil, which is the base stock for Brad Penn Racing Oils, has a naturally occurring wetting agent that enables the oil to stay put and resist slinging for an extended period of time. That’s important for critical areas such as flat-tappet cams and pistons/cylinder walls. After all, oil staying put means that it can better do its job of lubricating and protecting those internal engine components.

Regardless of the type of oil you choose to run, Speed and Glady agree that you should remain consistent with your brand choice. “The worst thing you can do to your motor is change your brand of oil regularly,” says Speed.

“You shouldn’t mix oil brands because each brand is typically formulated with a select balance of additive systems that are unique,” adds Glady.

Different oils and lubricants have different additives that can, at the very least, compete with one another and in the worst case scenario cancel each other out. Remember when you drain the oil from your engine the internal components that were exposed to the additive package still have those additives on their surfaces.

Speed says, “Be consistent with a good quality brand, and change the filter regularly.”

In addition to buying a race specific oil, you can also use a conventional oil and then buy a zinc additive to put into the oil, thereby boosting the zinc levels to the necessary 1,500 ppm that Glady spoke of. Richard Iskendarian of Isky Racing Cams says, “As far as oils go, we highly recommend the Brad Penn Racing Oil and Joe Gibbs Racing Oil. However, if customers prefer to use other oils without a high zinc content, we recommend a product called ZDDP Plus which replaces the EOS that GM discontinued about the middle of last year. The ZDDP Plus will take a sub-par oil and boost the zinc levels considerably. However, you should not add the ZDDP Plus to Brad Penn or Joe Gibbs as these already have generous amounts of zinc already.” That would upset the balance Glady spoke of.

Comp Cams just introduced a new surface treatment available on all their products, Pro Plasma Nitriding. The process treats a narrow band of 1.5 to 2 thousanths deep on the surface, thereby increasing its hardness by about 15 pts on the Rockwell scale. In a nutshell, it eliminates any type of break-in problems.

The origin of Pro Plasma Nitriding is interesting to say the least. “Years ago we’d sell a lot of the 2300 Pinto cams,” says Scooter Brothers. “Everybody here used to laugh about them and call them boomerang cams because they always came back with flattened lobes. Then somebody got this wild hair to try nitriding them. So we sent them to a place in Michigan. Once we started nitriding them, all of a sudden we didn’t have any more problems.”

With the rise of the sport compact movement, the Pinto cams and similar designs found a new home, and with the increased business the guys at Comp decided to buy their own machine and Pro Plasma Nitriding was born. “It’s the closest thing that I’ve ever seen that enables me to say it absolutely stops the problem. I hate to say 100 percent assurance that it won’t go flat, but knock on wood I haven’t seen any problems.”

Synthetic oils are all the rage, but that doesn’t necessarily mean they are good for racing applications. “The lubricity of synthetics is too much for a break in process,” says Dick Glady, who recommends a break-in specific oil when firing up that new engine for the first time. And while they have their place in the industry, you don’t need to run a full synthetic in your race motor. In fact, Brad Penn’s synthetic blend oils have only 10 percent synthetic base stock. They’ve found that percentage is optimum in delivering better oxidation stability on the top end.

At the end of the day, if you’re running a flat-tappet cam motor (and there are a lot of you out there) you owe it to your racing program to choose the right oil for your application. If you’re building a motor, you need to use a good racing assembly lubricant, the proper break in oil and finally a good racing oil, like one of the brands mentioned here. Don’t hesitate to contact the manufacturer of the oil or the cam as they will be more than happy to answer any of your questions. Remember using the proper oil may be the easiest thing you can do to prevent an unwanted cam failure.

From Hot Rod

From ΞSourceΞ.

Related Resources:

Topic Pages w/Directories, Vendors, Products: Media: Books, Websites, etc.

Categorized by Topic & Hierarchy w/Links (Sitemap).

TABLE KEY: Resource Types are identified by the following Resource Codes (RC).

T = Topic Page.

TD = Topic Page w/Directory

V = Vendor Page.

VO = Vendor's Offerings.

VW = Vendor's Website.

MV = Media Vendor/Creator.

MS = Media Source.

P = Product Page.

PD = Product Documentation.

B = Book.

BB = Book - Biography.

BE = Book Excerpt.

BF = Book - Fiction.

M = Magazine.

MI = Magazine Issue.

MA = Magazine Article.

Vid = Video.

W = Website.

WA = Website Article.

WV = Website Video (incl. YouTube).

F = Forum.

FP = Forum Post.

S = Social Media.

SP = Social Media Post.

NOTES: Resource Codes are arranged above by resource directory hierarchy.

Resource Codes are displayed in the Right Column labeled "RC". ⇒ ⇒ ⇒ ⇒ ⇒ ⇒ ⇒ ⇒ ⇒ ⇓

Resource Codes which are BOLD indicate Media is available from our Academy eLibrary.⇒ ⇓

^ To view Media, Click on the Media Title to go to our webpage for that media and then:

^ ^ Scroll down to the Academy eLibrary section for media viewing instructions.

Resource Media (Books, Magazines, Videos, etc.) Titles are displayed in a smaller font.

Resource Titles below are arranged by hierarchy using "^" to show subordination.

Resource Links which are BOLD lead to EverythingAboutBoats.com ON-SITE pages.

Resource Links which are NOT BOLD lead OFF-SITE. We is not responsible for their content.

If a link fails or we should add a resource to this listing, please submit info via email to:

^ Editor♥EverythingAboutBoats.org (Replace "♥" with "@")

If any Related Resources should be added to this list, please submit info/links via email To:

Editor♥EverythingAboutBoats.org (Replace "♥" with "@")

NOT AN ACADEMY MEMBER?

CLICK HERE to discover how you can become a Member and gain FULL access to

thousands of expanded pages and dozens of excellent programs including our eLibrary!

CLICK HERE to view ALL the books, magazines, videos, etc. in our Academy eLibrary.

Media are also listed by category on the Topic Pages found on the Right Sidebar ⇒

CLICK HERE to donate any books, magazines, manuals, or videos, etc. to our Library.

EVERYTHING ON THIS PAGE OK?

If there is anything on this webpage that needs fixing, please let us know via email To:

Editor♥EverythingAboutBoats.org (Replace "♥" with "@")

THIS ARTICLE IS STILL EVOLVING!

The page may contain rough drafts that include raw source materials.

Visit our FEATURED ARTICLES Home Page

to see examples of our website's comprehensive contents!

Thanks to our amazing contributors for the steady flow of articles, and to our dedicated all-volunteer staff who sort, polish and format them, everyday we get a little bit closer to our goal of

Everything About Boats. If you would like to submit an article,

See Submitting Articles.

— TOP 20 MOST POPULAR ARTICLES —

Detroit Diesel 8.2 Liter “Fuel Pincher” V8 Engine

Cummins V-555 & VT-555 “Triple-Nickel” V8 Diesel Engine

Lehman 120 (6D380) Diesel Engine (Ford 2704C & 2715E)

Ford Industrial Power Products Diesel Engines

How to Identify Ford Diesel Engines

Ford 2715E Diesel Engine

Lehman Mfg. Co.

Perkins Engines

Universal Atomic 4

Sears Boat Motors: Motorgo, Waterwitch, Elgin, etc.

Chrysler & Force Outboards

Eska Outboard Motors

Allison Transmission

ZF Friedrichshafen AG

Marine Surveyors by Country

American Marine Ltd (Grand Banks)

Boat Inspection (Types of Marine Surveys)

Boat Builders: (A∼Z) (w/Vessel Types, Locale & Years Active)

USCG NVIC 07-95 Guidance on Inspection, Repair and Maintenance of Wooden Hulls

American Boat and Yacht Counsel (ABYC)

Layout of the EverythingAboutBoats.org Website's Pages

— Types of Webpages —

This website consists almost entirely of 3 types of webpages as follows:

- TOPIC PAGES (See Main Topic Pages listed on Website Contents or the Right Sidebar) ⇒

- EXAMPLE: – WEBSITE CONTENTS w/Links to MAIN TOPIC & Subtopic Pages:

- EXAMPLE: 02 – BOAT BUILDING, OUTFITTING, REFITTING & REPAIR:

- EXAMPLE: 02.06 – Boat Equipment:

- EXAMPLE: 02.06.08 – Propulsion Machinery:

- EXAMPLE: 02.06.08.01 – Engines w/Directory of Vendors.

- VENDOR PAGES (Vendors of Products, Services, Events,+, Destinations & Media Creators)

- EXAMPLE: 02.06.08.01 – ^ Ford Industrial Power Products Diesel Engines.

- PRODUCT PAGES (Equipment, Events, Media: pDoc, Books, Magazines, Videos, Websites,+)

- EXAMPLE: 02.06.08.01 – ^ ^ Ford 2715E Diesel Engine.

- EXAMPLE: 02.06.08.01 – ^ ^ Ford OpManual - 2710 Range Diesel Engines.

- EXAMPLE: 02.06.08.01 – ^ ^ Ford Service Manual - 2700 & 2710 Range Diesel Engines.

Clickable Links that lead to other webpages appear in Blue Text and usually open in a new window.

Links in the Right Sidebar and most directories open in the current window, not a new window.

Note in the examples above that these pages form a natural hierarchy.

The unnumbered "^" pages are listed alphabetically in most tables.

Media Titles in tables are distinguished by their smaller font size.

Media (Books, Magazines, Videos, Articles,+) are treated as Products.

Vendors' Product Documentation (pDoc) are considered Media.

Destinations & Media Creators are treated as Vendors.

All Website Pages are optimized for viewing on

full-width disktop computer monitors,

but can be viewed on phones.

— Contents of Webpages —

Website Pages typically contain the following Sections:

- PATH (Shows the chain of EAB pages w/links that lead to the page being viewed).

- EXAMPLE:

PATH: HOME, WEBSITE INDEX, WEBSITE CONTENTS » ∨

∧ BOAT BUILDING & REPAIR » Boat Equipment » Propulsion » Engines » ∨∨

∧∧ Ford, Ebro, American Diesel, AmMarine, Barr, Beta, Bomac, Bowman, Couach,

Lees, Lehman, Mermaid, Parsons, Renault, Sabre, Thornycroft, Wortham Blake »

∧ DO-IT-YOURSELF » DIY Boat Building & Repair » DIY Schools & Classes »

∧ MEDIA w/Creator Directory » Documentation, Books, Magazines, Videos, Websites » - (The "»" right pointing Guillemet symbol shows the chain through the page links.)

- (The "," comma between page links in the chain indicates pages are not subordinate, but are instead at the same level. See engine brands in the example above.)

- (The "∨", "∨∨", "∨∨∨",+ symbols indicate that the path line continues with whatever follows the "∧", "∧∧", "∧∧∧",+ symbols respectively. "∧" Precedes each MAIN TOPIC Page.)

- EXAMPLE:

- PAGE CONTENTS (Table of Contents with links to each main section on the page).

- PAGE BODY (The type of page determines the contents of its body as follows:).

- TOPIC PAGES (Topic Treatment: Introduction, Overview, Background, Details,+).

- (Many Topic Pages contain Directories of Vendors with Links).

- (Most Directory Listings are Alphabetical and/or by Locale).

- VENDOR PAGES (Vendor's Profile, Contact Information, Products, Services,+).

- (Manufacturers, Resellers, Refitters, Yards, Surveyors, Clubs, Schools, Authors,+).

- (Boating & Travel Destinations are treated as Vendors on their own Vendor Pages).

- PRODUCT PAGES (Product Features, Vendor Links, Specifications, Documentation,+).

- (Media created by a vendor is often treated as a Product on its own Product Page).

- (Boating & Travel Events are often treated as Products on their own Product Pages).

- TOPIC PAGES (Topic Treatment: Introduction, Overview, Background, Details,+).

- RELATED RESOURCES (Topics, Vendors, Products, Media: Books, Websites,+ with Links).

- PAGE TAIL Contains the following Anchors Aweigh Academy & EAB Website Features:

- The Anchors Aweigh Academy's EverythingAboutBoats.org Header.

- A link to our Featured Articles EAB Home Page.

- Top 20 Most Popular Articles. (The section that appears right above ⇑ this section).

- Layout of the EverythingAboutBoats.org Website's Pages. (This very section ⇐).

- Topics of Webpages. (The very next section below ⇓).

- What we have accomplished so far.

- Members must Sign-In to gain full access to Expanded Pages & Programs.

- Sign-Up (if not already a member).

- Public Comments (about the website & about this page).

- RIGHT SIDEBAR (Website Contents menu with links to Main Topic & Subtopic pages).

(On some smart phones, the Right Sidebar may appear at the bottom of the webpage)

— Topics of Webpages —

Website Pages are categorized under the following 16 MAIN TOPICS:

The MAIN TOPICS follow a natural progression from conception of the vessel thru its

building, marketing, survey, financing, insuring, transport, moorage, use and upkeep.

The MAIN TOPICS (all Caps) below are followed by their Main Subtopics with Links.

00 – HOME: CONTENTS, ABOUT EAB: Contact EAB, Abbreviations & Symbols, FAQ, GLOSSARY, ADs,+.

01 – ABOUT BOATS w/Museum Directory: Early History, Recent History, Modern Vessel Types,+.

02 – BOAT BUILDING, OUTFITTING, REFITTING & REPAIR: Materials, Equipment, Builders,+.

03 – BOAT MARKETING: Boat Shows, Dealers & Brokers, Importing & Exporting, Auctions & Sales,+.

04 – BOAT INSPECTION: Types of Marine Surveys, Marine Surveyors, Schools, DIY Inspections,+.

05 – BOAT TITLES & VESSEL REGISTRY: Boat Title & Registration, Vessel Registry, Title Co's,+.

06 – BOAT FINANCING: Conventional (Banks, Credit Unions,+), Unconventional (Creative),+.

07 – BOAT INSURANCE: Maritime & Recreational: Coverage, Carriers, Agents,+., Claim Processing,+.

08 – BOAT TRANSPORT: By Sea (Piggyback, Delivery Skippers & Crews, & Towing), Over-Land,+.

09 – BOAT HAULING & LAUNCHING: Drydocks, Ways, Lifts, Cranes & Hoists, Launch Ramps,+.

10 – BOAT MOORAGE & STORAGE: Builders, Anchorages, Marinas, Yards, Racks & Stacks,+.

11 – BOATING ORGANIZATIONS: Yacht Clubs & Sailing Clubs, Paddling Clubs, Boat Owners,+.

12 – BOATING & TRAVEL: Events, Destinations, Boat Rentals & Charters, Cruises, Voyages,+.

13 – BOATING & MARITIME EDUCATION: Recreational Seamanship, Ship's Master & Crew,+.

14 – MARINE LAWS & REGULATIONS: International & National Laws‚ Lawyers‚ Investigators‚+.

15 – DO-IT-YOURSELF: DIY Boat Building & Repair, DIY Boat Sales, DIY Boat Surveys, DIY Classes,+.

16 – MEDIA w/Creator Directory + Academy eLibrary: pDocs, Books, Magazines, Videos, Websites,+.

The above MAIN TOPICS and a more detailed listing of Subtopics

can be found on the Website Contents page and on the Right Sidebar.

An Alphabetical Index of the website can be accessed at Website Index.

What we have accomplished so far.

Anchors Aweigh Academy and its EverythingAboutBoats.org website.

- Published over 50,000 website pages about boats and boating, bringing us closer to reaching our goal of becoming "The ultimate reference resource about boats and ships for everyone from the beginning recreational boater to the seasoned professional mariner!"

- Published over 300 website main topic webpages, many with full articles on the topic. See our Website Contents or the Right Sidebar for the listing of the main topic pages.

- Published over 9,000 marine vendor webpages, all with their contact information, most with a description of their products and services, many with product documentation, specifications and independent reviews. (incl.: Boat designers, boat building tools, material and equipment manufacturers and suppliers, boat builders and dealers, yacht brokers, marine surveyors, boat insurers, boat transporters, skippers and crews, boatyards and marinas, yacht clubs, boat rentals and yacht charters, boating, seamanship and maritime schools, marine law attorneys and expert witnesses, boat refitters and repairers, book authors, magazine publishers, video producers, and website creators)

- Acquired over 120,000 pages of product documentation including Catalogs, Brochures, SpecSheets, Pictures, Serial Number Guides, Installation Manuals, OpManuals, Parts Catalogs, Parts Bulletins, Shop Manuals, Wiring Diagrams, Service Bulletins, and Recalls. And have made all viewable to Academy Members through our EAB website eLibrary.

- Acquired over 1,200 books and magazine back issues in our academy library and so far have made over 700 viewable to Academy Members through our EAB website eLibrary.

- Published over 500 DIY How-To articles about boat design, construction, inspection, operation, maintenance, troubleshooting and repair. We are working hard to do more.

We are currently formatting and polishing the Anchors Aweigh Academy online and hands-on courses. Our Marine Surveying course has proven to be excellent for both the beginner and the seasoned surveyor, and especially helpful to the Do-It-Yourselfer.

Current Academy Members must SIGN IN to gain FULL access to this

website including expanded pages and valuable Academy programs

like our Academy eLibrary and our Ask-An-Expert Program!

If your membership has expired, CLICK HERE to Renew.

IF YOU ARE NOT YET AN ANCHORS AWEIGH ACADEMY MEMBER,

CLICK HERE to discover how you can become a Member and gain FULL access to

thousands of expanded pages and articles, and dozens of excellent programs

WITH JUST A SMALL DONATION!

Comments for Public Viewing

Submit any comments for public viewing via email To: Comments♥EverthingAboutBoats.org (Replace "♥" with "@")

Please remember to put this webpage's title in the subject line of your email.

All comments are moderated before they appear on this page. See Comment Rules.

General Comments About the Website

FROM Donald: "This is an awesome website. I found the information that I needed right away from one of the over 20,000 free articles that you provide as a public service. I'm surprised that so much if this site is free. But I still signed up so I could access the thousands of expanded pages, interesting articles, and dozens of valuable programs! The member's library of books, magazines and videos that I can view online is really terrific! I understand that you and your staff are all unpaid volunteers. Please keep up the good work. And I commend you for your plans to add another 10,000 free informative articles over the next year. I'm thrilled to support you in this endeavor with my small membership donation. Thanks again for all your hard work."

FROM Huey: "I agree with my Uncle, I too have found the articles to be very enlightening. They say that it will take about 100,000 articles to cover the full scope that they have envisioned for the website. They have over 20,000 articles so far and that's doing pretty well, but it could take several years to get the rest. I also noticed that many of the Main Topic Pages and some of the article pages are still in the rough draft stage. I guess that they will fill in as they can get volunteers to work on them. But what I can't figure out is why anyone would spend the time writing informative in depth articles just to give away free to this website for publication? What's in it for them?"

FROM Dewey: "Well Huey, to me It looks like most of the articles on this website are written by very informed people, like boating instructors, boat designers, boat builders, riggers, electricians, fitters, marine repair technicians and marine surveyors. Writing such articles helps establish them as knowledgeable professionals. After all, this website was originally created by a school for marine technicians and marine surveyors. The website is growing in content every day. They even had to move to a bigger, more powerful server because the website's traffic has been growing exponentially."

FROM Louie: "I agree with everyone above. This site is quickly becoming the ultimate reference resource about every aspect of boats and ships for everyone from the beginning recreational boater to the seasoned professional mariner. I use the topic pages on the right sidebar to browse around the website. It's like a Junior Woodchucks' Guidebook for Boaters. Their Members' Library of over 300 popular and obscure books and over 200 magazine back issues that can be viewed online is fabulous. The Academy's magazine is especially informative. On top of that, there is the "Ask-An-Expert program for members where you can get an expert's answer to any of your boat questions. And a whole years membership is only $25. What a deal! I really love being part of this "Everything About Boats" community and help provide thousands of helpful articles free to the public. I think that I'll sit down right now and write an article about my experiences boating with my uncle."

FROM Scrooge: "You rave about this website like it was the best thing since sliced bread. Well, I think it stinks. Sure, it has a lot of good information for boaters, and they're adding more every day, but it will probably never be finished. Furthermore, I don't even own a boat. And I wouldn't have a boat even if someone gave me one. Boats are a waste of money and time and energy and money! They're just a hole in the water you pour money into. If you gave me a boat, I'd sell it quicker then you could say Baggywrinkle. Then I'd lock up the cash with all my other money so I could keep my eye on it and count it every day. Bah humbug."

FROM Daisy: "I'm just so glad that Donald got the boat so we and the boys could enjoy boating — together. And of course all of the girls, April, May, and June, love to be on the water too, especially when that is where the boys are. Oh poor Scrooge, boating is more fun then you could possibly imagine."

FROM Scrooge: "After seeing how much fun you all have on the water together, I regret that I didn't have that much fun when I was young. I've had a change of heart, and I'm giving each of you a Lifetime Academy Membership."

FROM Editor: "For those of you that have stayed with us this far, many thanks, and we hope that you found this little narrative informative. Your faithful support inspires us to keep working on this phenomenal website. We know that we have a lot more to do. Ultimately, we hope that we can help you enjoy the wonder filled world of boating as much as we do. We are all waiting to see what you have to say about this webpage article. Submit any comments via email To: Comments♥EverythingAboutBoats.org (Replace "♥" with "@"). Be sure to include this page's title in the subject line. Also, your corrections, updates, additions and suggestions are welcomed. Please submit them via email To: Editor♥EverythingAboutBoats.org (Replace "♥" with "@"). It has been truly amazing to see what we have been able to accomplished when we've worked together. Thanks to all those that have donated their valuable time and energy, and a special THANK YOU to all that have supported this cause with their membership donations."

Comments About This Particular Page

FROM ΞNameΞ: “Be_the_next_to_comment_about_this_page.” {230316}