PATH: BOAT BUILDING & REPAIR » Boat Equipment » Propulsion » Engines » Cummins »

PAGE CONTENTS: (click ⇒ to go to each section on this page)

⇒ Product Overview, Features, Vendors, Specifications, Years, Ratings,+.

⇒ ^ Product Documentation: Catalogs, Brochures, Ads, AdVids, SpecSheets, Manuals, Recalls,+.

⇒ ^ Related Resources: EAB Topics w/Directories, Vendors, Products: Media: Books, Websites,+.

⇒ Visit EAB's FEATURED ARTICLES Home Page to preview the vast scope of our website.

⇒ This Month's Top 20 Most Popular Articles on our EAB website.

⇒ Layout of the EverythingAboutBoats.org Website's Pages: Page Types, Contents, Topics,+.

⇒ What our nonprofit Anchors Aweigh Academy and its EAB website have accomplished.

⇒ Members must SIGN IN to gain access to Members Only areas of this website.

⇒ Become an Academy Member and gain access to additional pages and programs!

⇒ Comments: Submit To ⇒ Comments♥EverythingAboutBoats.org (Replace "♥" with "@").

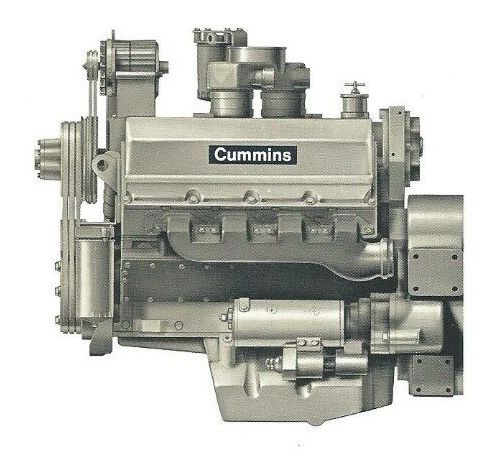

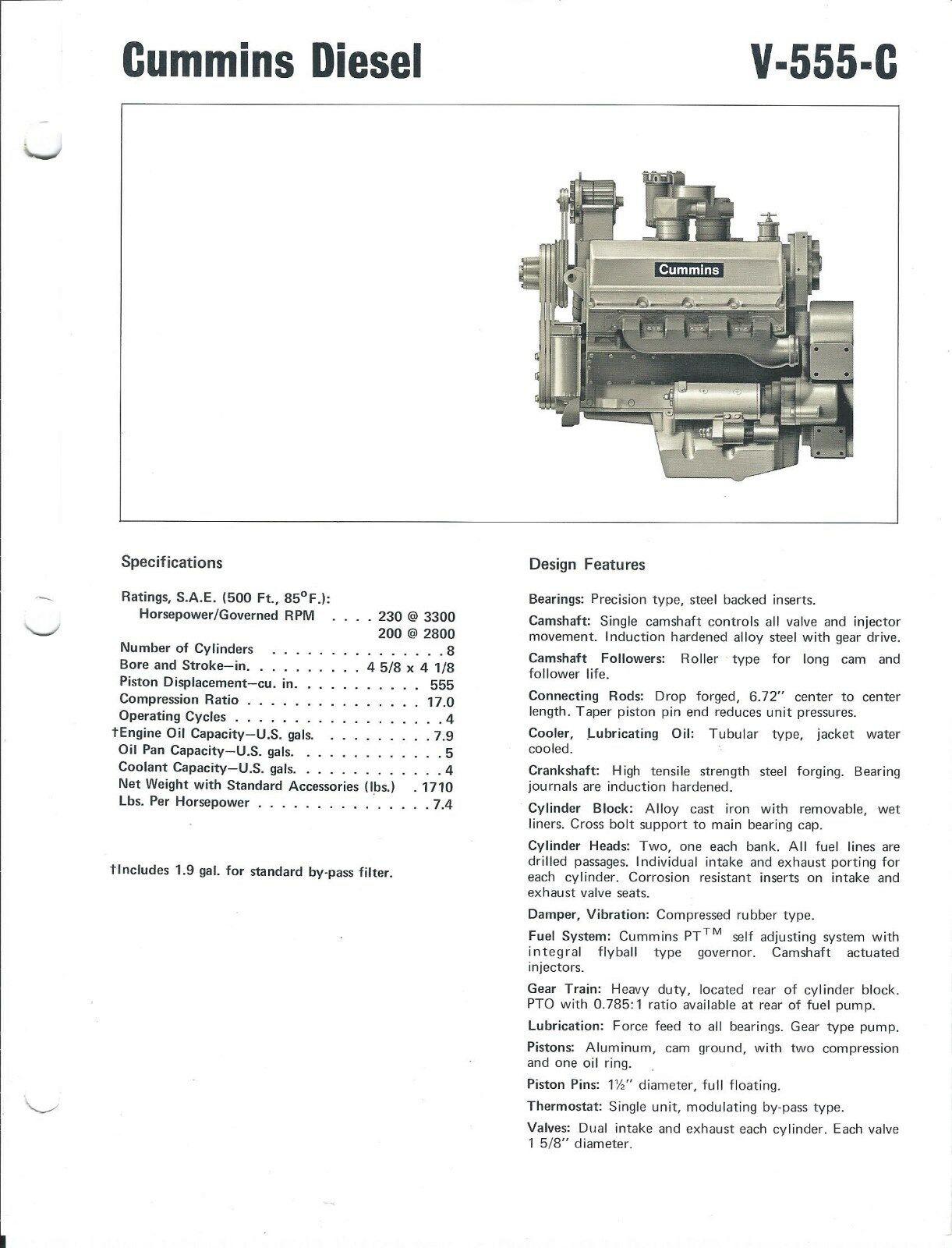

The Cummins V−555 and VT−555 are 555 cubic inch displacement V8 diesel engines produced by Cummins from 1968? to 1979?. It featured overhead valves actuated by rockers, push rods, and roller tappets by a roller camshaft located in the valley of the “V” between cylinder banks, parallel to the horizontal crankshaft. the eight cylinders had “Wet” cylinder liners and direct injection with the injectors being actuated by rockers, push rods, and roller tappets by the camshaft. The engine was available naturally aspirated (V−555) and turbocharged (VT−555).

The turbocharger was fitted to the VT−555 primarily to allow the 555 to develop its Sea Level rated horsepower in the thinner air found at higher altitudes, NOT to increase the overall power rating like most other turbocharged diesel engines as this would overstress the lightly-built internal engine components including the crankshaft bearings and cylinder liners. Therefore, the V−555 naturally aspirated engine and VT−555 turbocharged engine are both rated at the same maximum horsepower at sea level and up to 500 feet altitude (see the Specification Table).

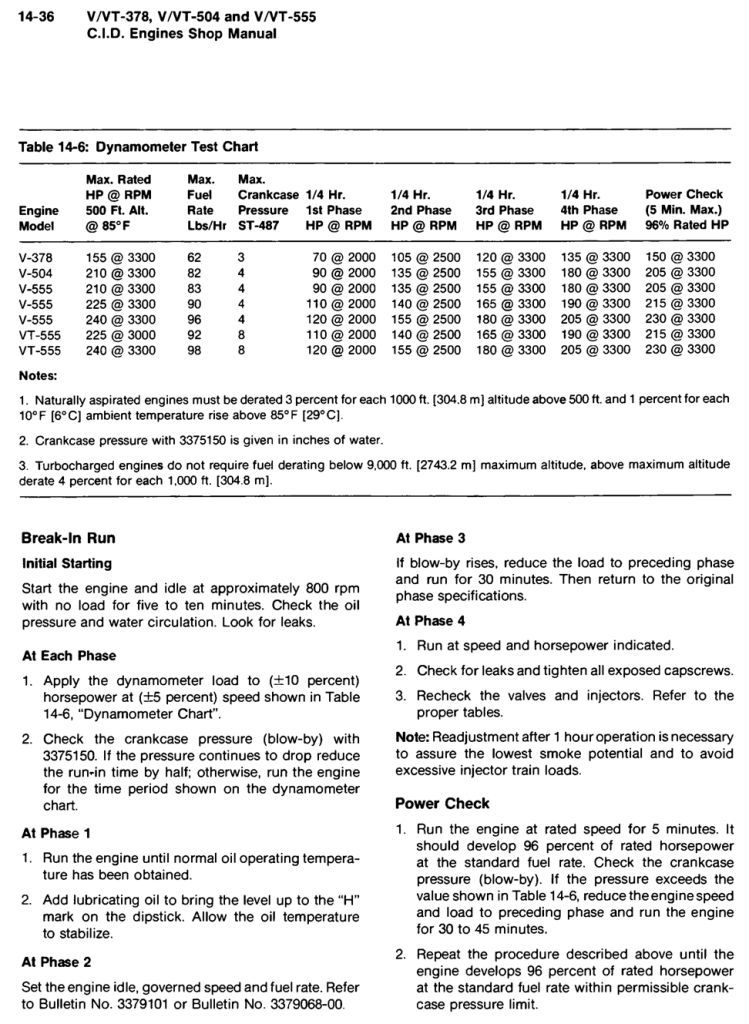

Naturally aspirated engines must be fuel derated 3% for each 1000 feet altitude above 500 feet and 1% for each 10°F (6°C) ambient temperature rise above 85°F (29°C) as warm air is less dense. Turbocharged engines do not require fuel derating below 9,000 feet (2743.2 m) maximum altitude, but above 9,000 feet altitude must be derate 4% for each 1,000 feet (304.8 m) (see the 555 Specification Table, SpecTable Notes, SpecSheet & Shop manual). Note that the Compression Ratio for Naturally Aspirated engines is 17:1 and Turbocharged engines is 16:1.

In an automotive application, fuel derating should be accompanied by a higher gear reduction in the rear end or shifting to a lower gear. In a marine application this is accomplished with a higher gear reduction or less propeller pitch (under-pitching) or both. Vessels operated at sea level benefit little from the standard-boost VT−555 air charging. VT−555 marine engines operated above 500 feet altitude (lakes, rivers, etc.) DO benefit from the standard turbocharger and do not required fuel derating below 9,000 feet (2743.2 m) altitude.

Keep in mind that aftermarket high-boost air charging can overstress this light-built engine resulting in catastrophic engine failure and is therefore, NOT RECOMMENDED.

Click Cummins Engine Company to view

vendor’s profile, contact information, and offerings.

Cummins V & VT Series History

In the late 1960’s, Cummins saw the need for compact diesel engines to power pumps, generators, and farm equipment where load and engine speed were strictly controlled and relatively constant. Small V6 and V8 engines were seen as fitting these applications even though the shortness of the crankshafts forced the connecting rod bearings, crankshaft main bearings and the crankshaft webs to be very narrow and hence very weak which limits the maximum power output of the engine. Never the less, Cummins developed a family of 45/8” bore 4−stroke cycle V6 and V8 diesel engines of 378, 504 and 555 cubic inch displacement which were designated V−378, V−504 and V−555 respectively for the naturally aspirated models, and VT−378, VT−504 and VT−555 respectively for the turbocharged models.

The 378 cubic inch and 504 cubic inch engines had a 33/4” stroke and the 555 cubic inch engine had a 41/8” stroke, making the engines very much “Oversquare”. The 555 cubic inch engine quickly becoming known as the “Triple-Nickel”.

These engines proved to be barely sufficient when powering pumps, generators, and farm equipment provided they were not lugged, heavily loaded, or quickly accelerated. unfortunately, the fuel crisis of the early 1970’s resulted in these engines, especially the 555, being misfitted to medium duty trucks and school busses where they encountered higher loads, stop and go operation with the need for quick acceleration which quickly revealed their weaknesses. They became known as trouble−plagued engines that experienced catastrophic bearing failures, “thrown rods”, broken crankshafts and leaking liners. In these automotive applications, they also proved disappointingly underpowered. Aftermarket high boost turbocharging simply exacerbated the engine’s weaknesses.

A somewhat less serious problem caused mainly by improper operation was carbon buildout in the combustion chambers that often carbonized the exhaust valves and fouled the fuel injectors, causing a loss of compression, injector misfire, rough running and excessive soot in the exhaust smoke.

A more serious issue was that any lugging or overheating of the engine could quickly damage the “Wet” cylinder liner seals. This would result in engine coolant flooding the crankcase which could cause serious internal damage, including damage to the crankshaft bearings.

The 555 also found its way into marine service where it faired somewhat better, provided it was properly set up with the right gearing and propeller pitch, and then was properly operated. See more about this later in this article under “How to keep the ‘Triple-Nickel’ alive“.

Cummins “Triple-Nickel” Shortcomings

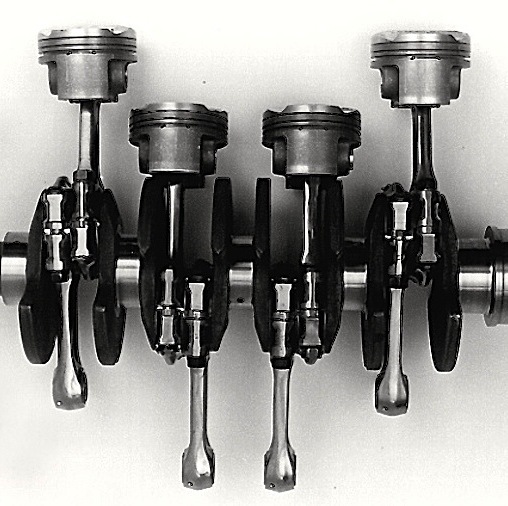

Unfortunately, the 555 suffers from several shortcomings including a “weak bottom end”. Reports of “broken cranks”, “spun bearings” and “thrown rods” NOT caused by “Hydrolocking” are far too frequent. This weakness, however is common of most smaller “V” cylinder configuration engines, especially those with cylinder bores less then 5 inches (127mm) and is due to the overall shortness of the crankshaft. Basically, the smaller the cylinder bore, the shorter the crankshaft, and the weaker the “bottom end”.

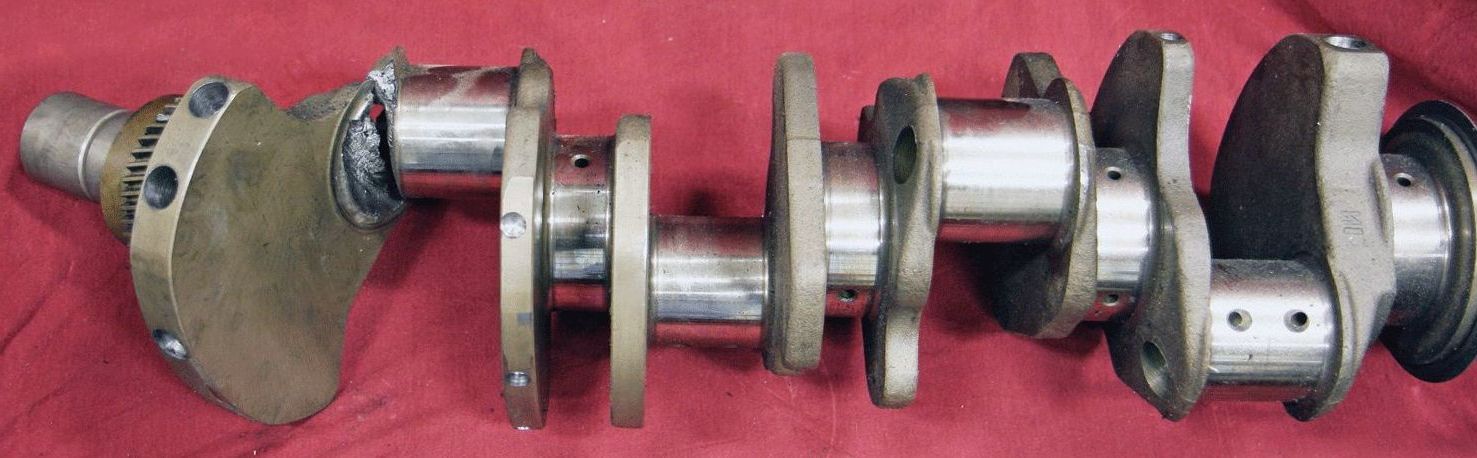

V8 Rod Bearings

Compare the narrow width of a small V8 engine’s connecting rod bearings above with the wider width of an inline 4-cylinder engine’s bearings below which are nearly twice as wide.

Inline-4 Rod Bearings

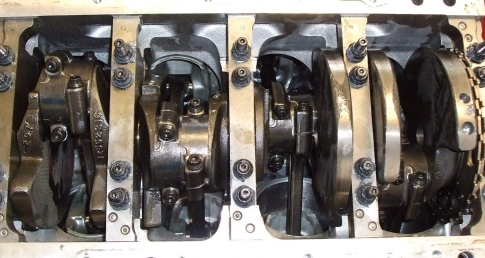

With twice as many pistons connected to a V8 crankshaft which is typically only slightly longer then an inline 4-cylinder crankshaft, there just isn’t much room for the connecting rod bearings, the crankshaft main bearings, and the crank webs. Consequently the V8’s bearings and webs must be much narrower as graphically shown in the picture above and the picture below. The red arrow below points to the connecting rod bearing insert ‘shell’ which is highlighted in red.

V8 Crankshaft and Connecting Rod with the narrow bearing shell highlighted in red.

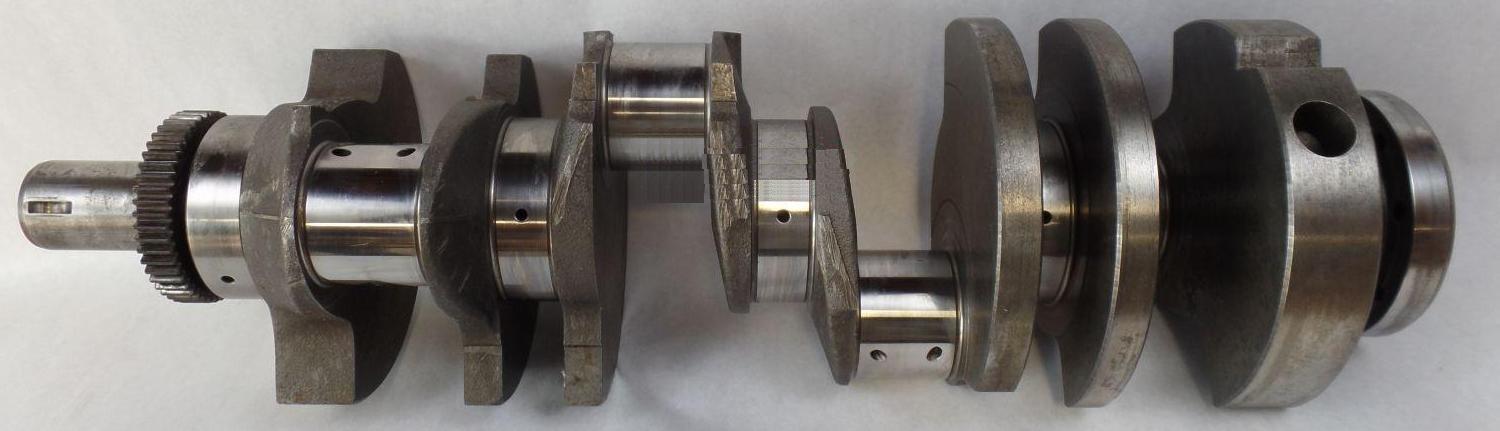

Obviously, in the case of “slip” type bearings like engine crankshaft bearings, the narrower the bearing, the more difficult it is for the lubricating oil to maintain an oil film between the bearing’s surface and the crankshaft that is adequate to support the heavy loads of a high compression diesel engine as the oil is forced out of a narrow bearing more easily, especially at higher RPM’s. The Detroit Diesel 8.2L crankshaft shown below is from another small V8 diesel engine that is prone to suffer crankshaft bearing failures due to the narrowness of the bearings.

Detroit Diesel 8.2 Crankshaft

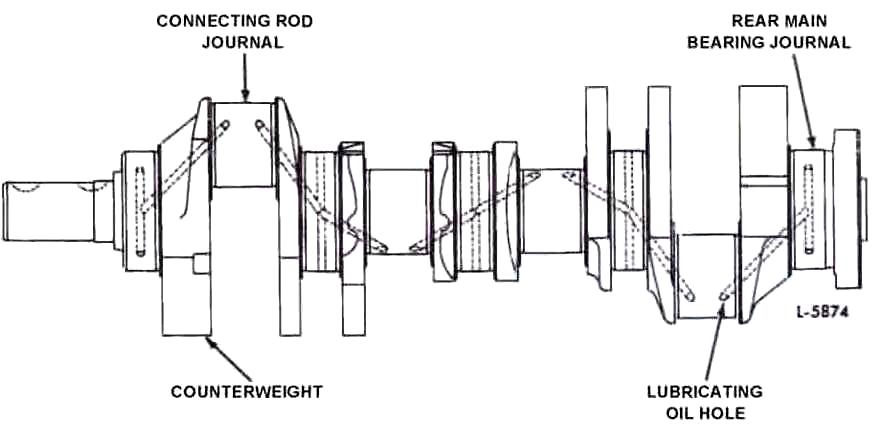

Even though the connecting rod pins on a V8 crank are the widest journals on the crank, when assembled the V8 crank will have two connecting rods crowded onto each rod journal leaving little room for each individual rod bearing.

V8 Crankshaft with Two Rods assembled to each rod Journal.

In the pictures above and the illustration below, it is easy to see how narrow the rod bearings have to be to fit on the short crankshaft of a small V8. Note the two oil feed holes per rod journal (one for each connecting rod. In a fully pressurized lubrication system, the oil is fed to the center of each bearing so that it can form an oil film between the crankshaft journal and the bearing surfaces, as it works its way to the outer edges of the bearing where it squirts out and splatters around the crankcase as the crankshaft turns. Oil tends to exit narrow bearings much more quickly. The wider the bearings, the more oil between the bearing and crankshaft surfaces to carry the load and the more slowly the oil is forced out from between the metal surfaces of the crankshaft and bearings, hence wide bearings can carry higher loads. The larger the cylinder bores, the longer the crankshaft and therefore the more room available for wider bearings. V8 engines with cylinder bores larger then 6″ typically have plenty of room on the longer crankshaft for wide bearings, etc.

Detroit Diesel 8.2 Crankshaft – Illustration.

Note how narrow the five main bearing journals are and how much larger their diameter when compared to those of the 4-cylinder crankshaft shown in the second picture below. Main bearings will be discussed in more detail a little later.

Another issue with any small V8 crankshaft is the narrow crank webs which are much weaker and consequently much more prone to breakage as shown below.

V8 Crankshaft with a broken web near front end of crankshaft (left).

By comparison, the inline 4-cylinder crankshaft shown directly below, which will have only one rod fitted per journal when assembled, can have much wider rod bearings. And note the much wider main bearing journals which will accommodate much wider main bearings. Also note the wider and much stronger crank webs between the bearing journals.

Detroit Diesel 4-53 4-cylinder 2-stroke cycle Crankshaft

The inline 4-cylinder crankshaft shown above has 5 main bearings. The crank webs, and the width and diameter of the main and rod bearings have been optimized to carry the stress and load of a high compression, high output engine. By comparison, the V8 crankshaft has the same number of main bearings for twice as many cylinders, and the V8 main bearing journals are much narrower. You can see how crowded a small V8 crankcase can be in the picture directly below. There just isn’t enough room for rod bearings or main bearings to be wide enough to carry the heavy loads generated by a high compression high output engine.

Notice that the main bearing journals of the V8 crankshafts shown in the illustration and pictures above have been increased in diameter to increase the bearing surface in an effort to compensate for their narrowness. But at some point this becomes counter-productive because the increased diameter increases the slip-bearing surface speed which makes it more difficult for the oil to maintain adequate oil film thickness at higher RPM’s. By comparison, a 4-cylinder crank’s main bearings can be wider so they can more easily maintain oil film thickness and carry the loads, hence the journals can be smaller in diameter to reduce bearing surface speed. This is why inline engines with the wider bearings and stronger crank webs, and main bearings between each cylinder can be air charged (e.g. with a turbocharger) to reliably produce more than twice the horsepower per unit of displacement then a small V8. Air-charging these stronger inline diesel engines can also enable them to run cleaner with fewer emissions. This benefit is discussed in detail in our article titled Fuel Fundamentals.

Engines with longer piston strokes have the advantage of being able to produce much higher torque at slower crankshaft speeds (RPMs). Many small V8 engines are designed with a stroke much shorter then most other diesel engines of the same displacement. The 555 is just slightly “over-square” with a 4 5/8” bore x 4 1/8” stroke. The shorter stroke allows the overall engine height to be lower. Unfortunately, like any of these short stroke, nearly-square and over-square engines, it produce less torque and has to be set-up to run at higher RPM’s to produce its maximum power, which has to be limited due to its increased crankshaft slip-bearing surface speeds, because as bearing surface speed increases, bearing wear increases, and so does the risk of bearing failure.

In conclusion:

The above comparisons show why smaller V8 engines that lack the space for the wider crankshaft bearings and stronger crank webs are not capable of the higher power outputs of comparable displacement inline engines. These are some of the main reasons why most diesel engine manufacturers have abandoned building small V8 engines and have embraced inline configurations especially the turbocharged 6 cylinder inline with 7 main bearings such as the Cummins B and C series engines. In the case of V8 engines with bores larger than 5 inches (127mm), the engine’s overall length is longer allowing the crankshaft to be longer, and therefore have more room for wider crankshaft bearings and stronger crank webs which means that they can have much stronger “bottom ends” and therefore higher power outputs per displacement unit then their smaller, shorter, and weaker little brothers.

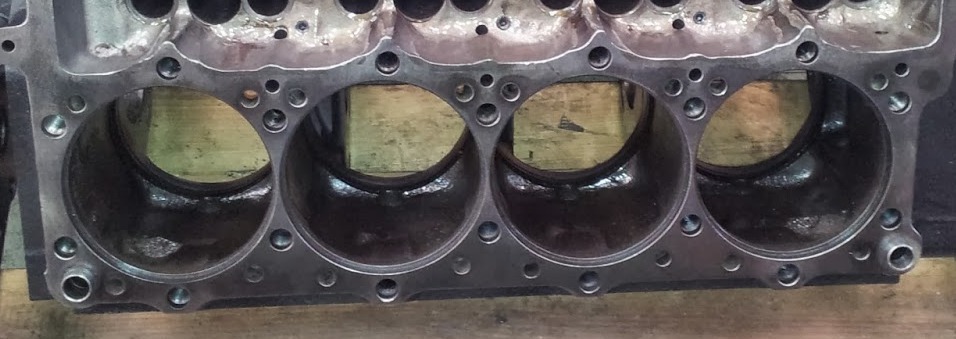

An additional issue with the 555 is that, any “liner shake” caused by lugging of the engine can quickly cause damage to the “Wet” cylinder liners and seals, and head gaskets that often results in engine coolant flooding the crankcase.

Cummins V−555 “Triple Nickel” Cylinder Block with replaceable “Wet” Cylinder Liners removed.

Another issue concerns quality replacement parts which are becoming scarce and more expensive. New major parts (i.e. blocks, heads, crankshafts, etc.) are practically non-existent and usable used parts are also becoming more scarce as more “take-outs” are simply scrapped.

How to keep the “Triple Nickel” alive

Because of these recognized inherent weaknesses, Cummins never did set up the 555 engines to produce very high power outputs especially when compared with the inline engines like the B and the C series engines. The V−555 (naturally aspirated) must be fuel derated above 500 feet altitude and the VT−555 (turbocharged) must be fuel derated above 9,000 feet altitude (See the Specification Table, SpecTable Notes, SpecSheet & Cummins Shop manual). Fuel derating should be accompanied by a gear reduction and In a marine application this includes a gear reduction and/or under-pitching the propeller.

When operating the 555, rapid acceleration or lugging (such as when towing another vessel or single engine operation of a twin engine vessel) should be avoided as this causes excessive internal stresses and over-fueling, even at slower RPMs. In such cases, a higher gear reduction and/or lower pitch propeller is advised.

If the 555 engine is intentionally operated at reduced power (below 80% of full power), by shifting down and easing up on the throttle, doing so has proven to help it survive. In a marine application this can be accomplished by higher gear reduction and/or under-pitching the propeller, which will stress the engine less, but will reduce the vessel’s cruising speed.

Unfortunately, running the engine at any slower RPMs and/or lower loads will lower combustion gas temperatures (below 800ºF) that encourages excessive soot with carbon buildup (carbonization) and its ensuing problems, including “injector misfire” and detonation. Since the practice of routinely running at full throttle (flank speed) and load to blow out the carbon soot is NOT recommended with the 555, because doing so risks catastrophic bearing failure, other ways of reducing carbon buildup must be utilized. Adding fuel additives that help keep fuel injectors clean and reduce carbon buildup can be quite useful.

Like many 4-Stroke Cycle engines, the 555 will tend to detonate when started in colder weather. Detonation is the phenomenon that occurs when the heated gases from combustion expand in the combustion chamber faster then the speed of sound and generate a supersonic shockwave. Detonation in a cold engine is the result of the increased ignition lag-time that unfortunately, delays ignition until the combustion chamber has an overabundance of fuel. Once ignited, the large quantity of fuel burns too fast, generating a shockwave. This shockwave or “sonic boom” if you like, can be heard by the naked ear as the characteristic “knock” or “ping” of detonation depending on the frequency of the sound, the “ping” being the higher frequency. Typically, the larger the cylinder, the lower the frequency. When detonation occurs in the 555, which mechanically injects the diesel fuel directly into the relatively fragile cylinder instead of into a heavily reinforced precombustion chamber, the shockwave too often causes damage to the head gaskets because they are directly exposed to the shockwave. Starting any diesel engine in cold temperatures is greatly improved by fitting an engine warming device such as a block heater or an intake air heater. Heating the incoming air reduces the ignition lag-time, avoiding detonation. Starting and running this engine in the summer with winter blend diesel which contains additives to improve starting in cold temperatures, can also cause internal damage from detonation and should therefore be avoided.

It is never a good idea to use “Ether” to start a 555 as it will often detonate in the cylinders causing head gasket damage or worse. Of course having such a volatile fuel as starting fluid in the engine space of a vessel, especially a diesel fueled one, is extremely dangerous. Why are volatile fuels such as starting fluid, gasoline or propane so dangerous in diesel powered vessels? Well remember that electrical devices such as relays, generators, alternators and starter motors on diesel engines in most vessels are not required to be ignition protected and therefore can provide an ignition source such as a spark resulting in an explosion and fire. Also, a diesel engine can “run away” on a volatile fuel in the engine space. So instead of using starting fluid, if the temperature is too cold for the engine to start easily, it is better to fit an engine warming device such as a block heater which is usually AC powered or an intake air heater which is usually DC and can be powered by the ship’s batteries.

Next, pay particular attention to the engine’s cooling system, especially the raw water pickup and sea strainer. Keep them clear of any obstructions. Also keep the raw water pump impeller, the heat exchanger, the engine coolant (antifreeze), the pressure cap, all hoses, and the engine belts and pulleys in good shape. The exhaust mixing elbows on wet exhaust systems should be routinely checked for deterioration and clogging. Even the slightest overheating can result in leakage of the wet cylinder liner seals as mentioned before. Make sure that an audible and visual (horn & light) engine overheat alarm is installed and operational and never continue to run the engine once the engine overheat alarm has sounded. Engines with wet exhaust systems would benefit from installation of exhaust system overheat alarms which give earlier warning when the raw water cooling supply is interrupted.

Fluid analysis of the engine coolant and engine oil can help detect deterioration and contamination of the fluids and can also help determine the extent of other internal damage.

It may also prove helpful to pull the fuel injectors and inspect the cylinders with a borescope for carbonization.

Ensure that the engine oil is properly maintained. Always use a quality Diesel Engine Lubricating Oil such as DELO 400 which still has a substantial amount of Zinc. DO NOT USE DELO 100 as it is a low detergent oil intended for Detroit Diesel’s 2-Stroke Cycle engines. See our webpage on engine oil. Always shake or stir the new oil container to mix the new oil before pouring the new oil into the engine as the oil and additives tend to separate over time. This is especially true of larger containers of oil such as drums which must be stirred routinely to mix the heavier additives like zinc that have settled to the bottom of the drum. Always maintain the proper oil level in the engine. Always replace the oil filter during every oil change. Then cut open the old filter and check it for metal. See our webpage on Inspecting Oil Filters for metal. Always use a quality oil filter. Consider fitting the engine with a by-pass oil filter in addition to the original full-flow oil filter. See our Article on Installing a Bypass Oil Filter. The small micron by-pass filter’s element can remove much smaller contaminate particles from the oil then the larger micron full-flow filter’s element can, thus reducing wear from oil contaminates. The V−555’s narrow crankshaft bearings make them more susceptible to wear from these smaller particles contaminating the oil when the oil film between the bearing and crankshaft is pressed thin.

Lastly, let’s consider one more source of wear and failure. If the engine sits dormant for long periods, consider fitting a pre-oiler to the engine to pressurize the oil galleys and fill the bearings before starting the engine. This practice reduces wear during startup, which is considerable especially in the case of the narrow V−555 crankshaft bearings. Pre-oilers are often fitted to commercial engines to reduce startup wear. See our webpage on Engine Pre-Oilers.

A surprising number of vessels were fitted with 555s for propulsion due to their rather reasonable original price. Unfortunately, due to the 555’s shortcomings, many of these engines are in trouble. Some of the owners aren’t aware of any problems, but again some are. There is no denying that the 555’s problems haven’t adversely effected the value of the vessels which are equipped with them. Whether you own such a vessel already or are considering buying one, a good place to start is with a fluid analysis of a properly drawn engine oil sample. Even when you don’t have any previous sampling results to trend from, The analysis of a single current sample can still reveal if any of the shortcomings inherent in the 555 have already resulted in damage to the engine and to just what extent. Academy members have the opportunity to submit oil analysis reports to our engine experts (at no charge) for their opinions and suggestions as part of our “Ask An Expert” Program.

If the 555 is currently in good condition, and your plan is to keep the engine for awhile, the best advise is to make the above improvements, keep it maintained, and run it easy. If you intend on keeping the vessel for a while, you should probably start budgeting for a repower. But remember that tight quarters may limit your choice of replacement engines. The Cummins B Series diesel engines have proven to be an excellent replacement if it will fit.

Similar engines produced by other manufacturers

During the 1970’s fuel crisis, Detroit Diesel saw the need for a cheap, fuel efficient engine to power medium trucks and school busses. Their answer was a lightweight, slightly under-square (108mm bore x 112mm stroke) 500 cubic inch displacement, four-stroke-cycle V8 diesel engine designated the 8.2 Liter and called the “Fuel Pincher“. The engine was eventually marinized by a few third-party companies (¿including Johnson & Towers?) and fitted to vessels, but they proved to be quite troublesome as they were prone to “blowing” head gaskets due to the “free-standing” cylinder design and lack of a proper “deck” to support the head, and also bearing failures due to its weak “bottom end”.

Caterpillar had came out with the 1100 medium truck engine in the 1960’s which became the 3160 marine engine. It was a larger bore V8 engine at 636 cubic inches of displacement, so it did not suffer as much from a weak “bottom end” as it’s smaller V8 rivals. However, in marine use, it sometimes suffered from a design flaw of the camshaft driven gear that resulted in the gear spinning on the camshaft during a “hard shift” or a “prop-strike” causing catastrophic internal damage to the engine. When Caterpillar came out with the 3208 (the 3160’s successor), they improved the strength of the “bottom end” slightly, but did nothing about the camshaft gear flaw. Installation of a “Drive Saver” propshaft coupling would be a wise investment as it could save the engine from such damage.

Specifications For Cummins “V” Series

4−Stoke Cycle V6 & V8 Diesel Engines

Features: Horizontal Crankshaft and “V” Pattern Wet Liner Cylinders

TABLE KEY:

Types of Engine Vendors: Engine design owners may produce the engines in-house as manufacturers.

^ Licensees are licensed by engine design owners to produce base engines and/or marine engines.

^ Marinizers buy base engines from the producers at wholesale, marinize them for marine service,

^ ^ and then sell them to boat builders, resellers, etc. at wholesale or to end users at retail.

^ Resellers buy marine engines at wholesale and resell them at a markup or at retail.

BASE ENGINE: Manufacturer/Vendor & Model of Base Engine followed by Specifications.

^ CYL: Cylinder Orientation & Configuration – (Dash w/no spaces) Number of Cylinders: (example: “V-8”)

^ ^ Cylinder Orientation: No Code = u… = Upright (Vertical).

^ ^ Cylinder Configuration: …V = V Pattern (eg V-8).

^ BORE & STROKE: …mm = Millimeters. …in = …” = Inches.

^ DISPLACEMENT = Swept Volume: …cc = Cubic Centimeters (cm³). …L = Liters. …ci = Cubic Inches (in³).

MODEL RATINGS: Base Engine Model, Vendor Rating Code, Duty Ratings, Power Ratings, etc.

^ A-F: Aspiration-Fueling: Intake Air uncharged or charged – Petrol or Diesel Fueling.

^ ^ Aspiration: N = Naturally Aspirated. T = Turbocharged. …i = Intercooled. …a = Aftercooled.

^ ^ Diesel Fueling: M = Mechanical Injection. …ii = II = Integral Injector. …d = Direct Injection

^ DR = Duty Ratings: See the Engine Duty Ratings Description at the end of the Table.

^ ^ ♦♦ = Highest Power Rating from Data Sources.

^ POWER: kW = Kilowatts. HP = Horsepower. BHP = Brake Horsepower. SHP = SAE Horsepower.

^ RPM = Power Ratings @ Revolutions Per Minute.

^ YEARS: Beginning-Ending. Trailing “–” (Dash) without an Ending Date = Still in Production/Available.

^ ^ YYYY usually = Model Year. MM/YY = actual Month/Year.

^ ^ Vendors typically market products after production ceases, often until stockpiles are exhausted.

^ DS = Data Source: Click DS Link to view DS. ♦♦♦ = Summary of Data Compiled from Multiple Sources.

^ ^ DS’s 1st Letter = Vendor’s 1st Letter (example: F = Ford). Wik = Wikipedia. BD = BoatDiesel.com.

^ ^ DS’s 2nd Letter: …d = Directory. …w = Webpage. …c = Catalog. …b = Brochure. …s = SpecSheet.

^ ^ ^ …o = Owner’s/Operator’s Manual. …m = Service/Repair/Technical/Workshop/Shop Manual.

^ ^ ^ …p = Parts Catalog. …# = Serial # List …h = History. …y = Years Vended (History). …f = Forum.

^ ^ DS’s Last Digits: …1,2,3,A,B,C,etc = Source #, Version, Revision (example: Fc1 = Ford Catalog #1).

Data: ⊗ = Data Not Available from Data Source. ¿… = …? = Data Unconfirmed/in Question.

Clicking a Vendor Link in the table will open a new window displaying our webpage for that Vendor containing details about that vendor and their products. Clicking a Model Link in the table will open a new window displaying our webpage for that Model.

HOW TO READ THIS TABLE

Each line displays the data available from the identified Data Source (DS). The data is displayed according to the Table Key above. Clicking on the Data Source Link will open a new window displaying that Data Source. Data Sources include Catalogs, Brochures, Ads, SpecSheets, Owners/OpManuals, Parts Catalogs, Shop Manuals and Articles. The Triple Diamond "♦♦♦" = Summary of data compiled from multiple Data Sources.

Keep in mind that Data can be inaccurate in the source material and sometimes, the source material may be illegible. We try to obtain the best source material available and we make corrections to the tables when needed. If you wish to point out an error or you can help us obtain good source materials, please let us know via email To: Editor♥EverythingAboutBoats.org (Replace "♥" with "@")

| BASE ENGINE: | ||||

| CUMMINS | CYL | BORE | STROKE | DISPLACEMENT |

| V−555 | V-8 | 117.5mm / 45/8in | 104.8mm / 41/8in | ⊗cc / 9.1L / 555ci |

| MODEL RATINGS: | ||||||||

| CUMMINS | A-F | DR | kW | BHP | MHP | RPM | YEARS | DS |

| V−555 (Automotive) | N-M | ♦♦ | ⊗ | 240 | ⊗ | 3300 | 1970±∼1980± | ♦♦♦ |

| ^ | N-M | ⊗ | ⊗ | 200 | ⊗ | 2800 | ⊗∼⊗ | Cs1 |

| ^ | N-M | ⊗ | ⊗ | 230 | ⊗ | 3300 | ⊗∼⊗ | Cs1 |

| ^ | N-M | ⊗ | ⊗ | 210 | ⊗ | 3000 | ⊗∼⊗ | Cm1 |

| ^ | N-M | ⊗ | ⊗ | 225 | ⊗ | 3000 | ⊗∼⊗ | Cm1 |

| ^ | N-M | ⊗ | ⊗ | 240 | ⊗ | 3300 | ⊗∼⊗ | Cm1 |

| V−555 (Industrial) | N-M | ♦♦ | ⊗ | 240? | ⊗ | 3300? | 1970±∼1980± | ♦♦♦ |

| ^ | ⊗-⊗ | ⊗ | ⊗ | ⊗ | ⊗ | ⊗ | ⊗∼⊗ | ? |

| VT−555 (Automotive) | T-M | ♦♦ | ⊗ | 240 | ⊗ | 3300 | 1970±∼1980± | ♦♦♦ |

| ^ | T-M | ⊗ | ⊗ | 225 | ⊗ | 3000 | ⊗∼⊗ | Cm1 |

| ^ | T-M | ⊗ | ⊗ | 240 | ⊗ | 3300 | ⊗∼⊗ | Cm1 |

| VT−555 (Industrial) | T-M | ♦♦ | ⊗ | 240? | ⊗ | 3300? | 1970±∼1980± | ♦♦♦ |

| ^ | ⊗-⊗ | ⊗ | ⊗ | ⊗ | ⊗ | ⊗ | ⊗∼⊗ | ? |

| MARINIZERS: | ||||||||

| V |

A-F | DR | kW | BHP | MHP | RPM | YEARS | DS |

| M |

⊗-⊗ | ♦♦ | ⊗ | ⊗ | ⊗ | ⊗ | ⊗∼⊗ | ♦♦♦ |

| ^ ^ | ⊗-⊗ | ⊗ | ⊗ | ⊗ | ⊗ | ⊗ | ⊗∼⊗ | ? |

| ^ M |

⊗-⊗ | ⊗ | ⊗ | ⊗ | ⊗ | ⊗ | ⊗∼⊗ | ? |

NOTES: The turbocharger is fitted primarily to allow the engine to develop its Sea Level rated horsepower in the thinner air at higher altitudes up to 9,000 feet. Naturally aspirated engines and turbocharged engines are rated at the same maximum rated horsepower at up to 500 feet altitude. Naturally aspirated engines must be derated 3% for each 1000 feet altitude above 500 feet and 1% for each 10°F (6°C) ambient temperature rise above 85°F (29°C). Turbocharged engines do not require fuel derating below 9,000 feet (2743.2 m) maximum altitude, above maximum altitude derate 4% for each 1,000 feet (304.8 m). Compression Ratio for Naturally Aspirated engines is 17.0:1 and Turbocharged engines is 16.0:1. See the SpecSheet & Cummins Shop manual.

Cummins

Engine Duty Ratings

Agricultural:

C = Continuous: Power available continuously.

I = Intermittent: Power available for 1 hour out of 8 hours with low annual hours.

Automotive:

C = Continuous: Power available continuously.

I = Intermittent: Power available for 1 hour out of 8 hours with low annual hours.

Industrial:

C = Continuous: Power available continuously.

I = Intermittent: Power available for 1 hour out of 8 hours with low annual hours.

Marine:

C = Continuous: Power available continuously.

I = Intermittent: Power available for 1 hour out of 8 hours with low annual hours.

Power Generation:

GC = Generator – Continuous.

GP = Generator – Intermittent Peak Load.

NOTES: AC Generators usually turn 1500 RPM for 50 Cycle and 1800 RPM for 60 Cycle.

The above Shop Manual is available from Barrington Diesel Club.

Product Documentation

Documentation with Bold Titles are part of our Academy eLibrary!

To view the entire document, click on its Bold Title Link to go to our webpage for

that item and then scroll down to the "Academy eLibrary" section on that page for link.

⇐ (arrow) = Document Creator is the vendor shown at the beginning of the title.

DS = Data Source for listed specifications.

| DOCUMENTATION TYPE: | |

| DOCUMENT TITLE – Products (Notes) — Creators – Sources | DS |

| Catalogs and Brochures: | ↓c/b↓ |

| ΞVendorΞ Catalog – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –c– |

| ΞVendorΞ Brochure – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –b– |

| AdVids: (Advertisement Videos) | ↓a↓ |

| ΞVendorΞ AdVids – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –a– |

| SpecSheets: (Specification Sheets‚ Data Sheets‚ FactSheets) | ↓s↓ |

| Cummins SpecSheet – V−555-C — Cummins | Cs– |

| Cummins SpecSheet – V−555-C — Cummins – Barrington Diesel Club | Cs– |

| Cummins SpecSheet – VT−555-C — Cummins | Cs– |

| ΞVendorΞ SpecSheet – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –s– |

| Charts and Graphs: (Power & Torque Curves) | ↓g↓ |

| ΞVendorΞ Chart/Graph – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –g– |

| Pictures: | ↓x↓ |

| ΞVendorΞ Picture (V |

–x– |

| Press Releases: (by Date: = YYMMDD) | ↓pr↓ |

| ΞVendorΞ Press Release (ΞDATEΞ) – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –pr– |

| Model History: | ↓h↓ |

| ΞVendorΞ Model History – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –h– |

| Serial Number Guides: (Date of Manufacture‚ Date Codes‚+) | ↓#↓ |

| ΞVendorΞ Serial Number Guide – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –#– |

| Installation Instructions: | ↓i↓ |

| ΞVendorΞ Installation Instructions – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –i– |

| Installation Drawings with Dimensions: | ↓d↓ |

| ΞVendorΞ Installation Diagram/Drawing – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –d– |

| OpManuals: (Owner's/Operator's Handbooks/Manuals) | ↓o↓ |

| ΞVendorΞ OpManual – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –o– |

| Parts Catalogs: (with Exploded Views & Parts Lists) | ↓p↓ |

| ΞVendorΞ Parts Catalog – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –p– |

| Parts Bulletins: (by Date: YYMMDD) | ↓pb↓ |

| ΞVendorΞ Parts Bulletin – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –pb– |

| Shop Manuals: (Repair/Service/Technical/Workshop Manuals) | ↓m↓ |

| Cummins Shop Manual – V/VT–378‚ V/VT–504‚ & V/VT–555 — Cummins | Cm1 |

| Cummins Shop Manual – V/VT–378‚ V/VT–504‚ & V/VT–555 — Cummins – Barrington Diesel Club | Cm1– |

| ΞVendorΞ Shop Manual – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –m– |

| Wiring Diagrams: | ↓w↓ |

| ΞVendorΞ Wiring Diagram – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –w– |

| TechVids: (Technical Videos: Service Training‚ etc.) | ↓v↓ |

| ΞVendorΞ TechVids (ΞDATEΞ) – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –v– |

| Service Bulletins: (by Date: YYMMDD) | ↓sb↓ |

| ΞVendorΞ Service Bulletin (ΞDATEΞ) – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –sb– |

| Product Recalls: | ↓r↓ |

| ΞVendorΞ Recall – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –r– |

| Other Documentation: | ↓?↓ |

| ΞVendorΞ ? – ΞProductsΞ (ΞNotesΞ) — ΞCreatorΞ – ΞSourceΞ | –?– |

If you can help us add documentation that we lack, please submit info/links or PDF via email To:

Editor♥EverythingAboutBoats.org (Replace "♥" with "@")

NOT AN ACADEMY MEMBER?

CLICK HERE to discover how you can become a Member and gain FULL access to

thousands of expanded pages and dozens of excellent programs including our eLibrary!

CLICK HERE to view ALL the books, magazines, videos, etc. in our Academy eLibrary.

Media are also listed by category on the Topic Pages found on the Right Sidebar ⇒

CLICK HERE to donate any books, magazines, manuals, or videos, etc. to our Library.

Related Resources:

Topic Pages w/Directories, Vendors, Products: Media: Books, Websites, etc.

Categorized by Topic & Hierarchy w/Links (Sitemap).

TABLE KEY: Resource Types are identified by the following Resource Codes (RC).

T = Topic Page.

TD = Topic Page w/Directory

V = Vendor Page.

VO = Vendor's Offerings.

VW = Vendor's Website.

MV = Media Vendor/Creator.

MS = Media Source.

P = Product Page.

PD = Product Documentation.

B = Book.

BB = Book - Biography.

BE = Book Excerpt.

BF = Book - Fiction.

M = Magazine.

MI = Magazine Issue.

MA = Magazine Article.

Vid = Video.

W = Website.

WA = Website Article.

WV = Website Video (incl. YouTube).

F = Forum.

FP = Forum Post.

S = Social Media.

SP = Social Media Post.

NOTES: Resource Codes are arranged above by resource directory hierarchy.

Resource Codes are displayed in the Right Column labeled "RC". ⇒ ⇒ ⇒ ⇒ ⇒ ⇒ ⇒ ⇒ ⇒ ⇓

Resource Codes which are BOLD indicate Media is available from our Academy eLibrary.⇒ ⇓

^ To view Media, Click on the Media Title to go to our webpage for that media and then:

^ ^ Scroll down to the Academy eLibrary section for media viewing instructions.

Resource Media (Books, Magazines, Videos, etc.) Titles are displayed in a smaller font.

Resource Titles below are arranged by hierarchy using "^" to show subordination.

Resource Links which are BOLD lead to EverythingAboutBoats.com ON-SITE pages.

Resource Links which are NOT BOLD lead OFF-SITE. We is not responsible for their content.

If a link fails or we should add a resource to this listing, please submit info via email to:

^ Editor♥EverythingAboutBoats.org (Replace "♥" with "@")

If any Related Resources should be added to this list, please submit info/links via email To:

Editor♥EverythingAboutBoats.org (Replace "♥" with "@")

NOT AN ACADEMY MEMBER?

CLICK HERE to discover how you can become a Member and gain FULL access to

thousands of expanded pages and dozens of excellent programs including our eLibrary!

CLICK HERE to view ALL the books, magazines, videos, etc. in our Academy eLibrary.

Media are also listed by category on the Topic Pages found on the Right Sidebar ⇒

CLICK HERE to donate any books, magazines, manuals, or videos, etc. to our Library.

EVERYTHING ON THIS PAGE OK?

If there is anything on this webpage that needs fixing, please let us know via email To:

Editor♥EverythingAboutBoats.org (Replace "♥" with "@")

Visit our FEATURED ARTICLES Home Page

to see examples of our website's comprehensive contents!

Thanks to our amazing contributors for the steady flow of articles, and to our dedicated all-volunteer staff who sort, polish and format them, everyday we get a little bit closer to our goal of

Everything About Boats. If you would like to submit an article,

See Submitting Articles.

— TOP 20 MOST POPULAR ARTICLES —

Detroit Diesel 8.2 Liter “Fuel Pincher” V8 Engine

Cummins V-555 & VT-555 “Triple-Nickel” V8 Diesel Engine

Lehman 120 (6D380) Diesel Engine (Ford 2704C & 2715E)

Ford Industrial Power Products Diesel Engines

How to Identify Ford Diesel Engines

Ford 2715E Diesel Engine

Lehman Mfg. Co.

Perkins Engines

Universal Atomic 4

Sears Boat Motors: Motorgo, Waterwitch, Elgin, etc.

Chrysler & Force Outboards

Eska Outboard Motors

Allison Transmission

ZF Friedrichshafen AG

Marine Surveyors by Country

American Marine Ltd (Grand Banks)

Boat Inspection (Types of Marine Surveys)

Boat Builders: (A∼Z) (w/Vessel Types, Locale & Years Active)

USCG NVIC 07-95 Guidance on Inspection, Repair and Maintenance of Wooden Hulls

American Boat and Yacht Counsel (ABYC)

Layout of the EverythingAboutBoats.org Website's Pages

— Types of Webpages —

This website consists almost entirely of 3 types of webpages as follows:

- TOPIC PAGES (See Main Topic Pages listed on Website Contents or the Right Sidebar) ⇒

- EXAMPLE: – WEBSITE CONTENTS w/Links to MAIN TOPIC & Subtopic Pages:

- EXAMPLE: 02 – BOAT BUILDING, OUTFITTING, REFITTING & REPAIR:

- EXAMPLE: 02.06 – Boat Equipment:

- EXAMPLE: 02.06.08 – Propulsion Machinery:

- EXAMPLE: 02.06.08.01 – Engines w/Directory of Vendors.

- VENDOR PAGES (Vendors of Products, Services, Events,+, Destinations & Media Creators)

- EXAMPLE: 02.06.08.01 – ^ Ford Industrial Power Products Diesel Engines.

- PRODUCT PAGES (Equipment, Events, Media: pDoc, Books, Magazines, Videos, Websites,+)

- EXAMPLE: 02.06.08.01 – ^ ^ Ford 2715E Diesel Engine.

- EXAMPLE: 02.06.08.01 – ^ ^ Ford OpManual - 2710 Range Diesel Engines.

- EXAMPLE: 02.06.08.01 – ^ ^ Ford Service Manual - 2700 & 2710 Range Diesel Engines.

Clickable Links that lead to other webpages appear in Blue Text and usually open in a new window.

Links in the Right Sidebar and most directories open in the current window, not a new window.

Note in the examples above that these pages form a natural hierarchy.

The unnumbered "^" pages are listed alphabetically in most tables.

Media Titles in tables are distinguished by their smaller font size.

Media (Books, Magazines, Videos, Articles,+) are treated as Products.

Vendors' Product Documentation (pDoc) are considered Media.

Destinations & Media Creators are treated as Vendors.

All Website Pages are optimized for viewing on

full-width disktop computer monitors,

but can be viewed on phones.

— Contents of Webpages —

Website Pages typically contain the following Sections:

- PATH (Shows the chain of EAB pages w/links that lead to the page being viewed).

- EXAMPLE:

PATH: HOME, WEBSITE INDEX, WEBSITE CONTENTS » ∨

∧ BOAT BUILDING & REPAIR » Boat Equipment » Propulsion » Engines » ∨∨

∧∧ Ford, Ebro, American Diesel, AmMarine, Barr, Beta, Bomac, Bowman, Couach,

Lees, Lehman, Mermaid, Parsons, Renault, Sabre, Thornycroft, Wortham Blake »

∧ DO-IT-YOURSELF » DIY Boat Building & Repair » DIY Schools & Classes »

∧ MEDIA w/Creator Directory » Documentation, Books, Magazines, Videos, Websites » - (The "»" right pointing Guillemet symbol shows the chain through the page links.)

- (The "," comma between page links in the chain indicates pages are not subordinate, but are instead at the same level. See engine brands in the example above.)

- (The "∨", "∨∨", "∨∨∨",+ symbols indicate that the path line continues with whatever follows the "∧", "∧∧", "∧∧∧",+ symbols respectively. "∧" Precedes each MAIN TOPIC Page.)

- EXAMPLE:

- PAGE CONTENTS (Table of Contents with links to each main section on the page).

- PAGE BODY (The type of page determines the contents of its body as follows:).

- TOPIC PAGES (Topic Treatment: Introduction, Overview, Background, Details,+).

- (Many Topic Pages contain Directories of Vendors with Links).

- (Most Directory Listings are Alphabetical and/or by Locale).

- VENDOR PAGES (Vendor's Profile, Contact Information, Products, Services,+).

- (Manufacturers, Resellers, Refitters, Yards, Surveyors, Clubs, Schools, Authors,+).

- (Boating & Travel Destinations are treated as Vendors on their own Vendor Pages).

- PRODUCT PAGES (Product Features, Vendor Links, Specifications, Documentation,+).

- (Media created by a vendor is often treated as a Product on its own Product Page).

- (Boating & Travel Events are often treated as Products on their own Product Pages).

- TOPIC PAGES (Topic Treatment: Introduction, Overview, Background, Details,+).

- RELATED RESOURCES (Topics, Vendors, Products, Media: Books, Websites,+ with Links).

- PAGE TAIL Contains the following Anchors Aweigh Academy & EAB Website Features:

- The Anchors Aweigh Academy's EverythingAboutBoats.org Header.

- A link to our Featured Articles EAB Home Page.

- Top 20 Most Popular Articles. (The section that appears right above ⇑ this section).

- Layout of the EverythingAboutBoats.org Website's Pages. (This very section ⇐).

- Topics of Webpages. (The very next section below ⇓).

- What we have accomplished so far.

- Members must Sign-In to gain full access to Expanded Pages & Programs.

- Sign-Up (if not already a member).

- Public Comments (about the website & about this page).

- RIGHT SIDEBAR (Website Contents menu with links to Main Topic & Subtopic pages).

(On some smart phones, the Right Sidebar may appear at the bottom of the webpage)

— Topics of Webpages —

Website Pages are categorized under the following 16 MAIN TOPICS:

The MAIN TOPICS follow a natural progression from conception of the vessel thru its

building, marketing, survey, financing, insuring, transport, moorage, use and upkeep.

The MAIN TOPICS (all Caps) below are followed by their Main Subtopics with Links.

00 – HOME: CONTENTS, ABOUT EAB: Contact EAB, Abbreviations & Symbols, FAQ, GLOSSARY, ADs,+.

01 – ABOUT BOATS w/Museum Directory: Early History, Recent History, Modern Vessel Types,+.

02 – BOAT BUILDING, OUTFITTING, REFITTING & REPAIR: Materials, Equipment, Builders,+.

03 – BOAT MARKETING: Boat Shows, Dealers & Brokers, Importing & Exporting, Auctions & Sales,+.

04 – BOAT INSPECTION: Types of Marine Surveys, Marine Surveyors, Schools, DIY Inspections,+.

05 – BOAT TITLES & VESSEL REGISTRY: Boat Title & Registration, Vessel Registry, Title Co's,+.

06 – BOAT FINANCING: Conventional (Banks, Credit Unions,+), Unconventional (Creative),+.

07 – BOAT INSURANCE: Maritime & Recreational: Coverage, Carriers, Agents,+., Claim Processing,+.

08 – BOAT TRANSPORT: By Sea (Piggyback, Delivery Skippers & Crews, & Towing), Over-Land,+.

09 – BOAT HAULING & LAUNCHING: Drydocks, Ways, Lifts, Cranes & Hoists, Launch Ramps,+.

10 – BOAT MOORAGE & STORAGE: Builders, Anchorages, Marinas, Yards, Racks & Stacks,+.

11 – BOATING ORGANIZATIONS: Yacht Clubs & Sailing Clubs, Paddling Clubs, Boat Owners,+.

12 – BOATING & TRAVEL: Events, Destinations, Boat Rentals & Charters, Cruises, Voyages,+.

13 – BOATING & MARITIME EDUCATION: Recreational Seamanship, Ship's Master & Crew,+.

14 – MARINE LAWS & REGULATIONS: International & National Laws‚ Lawyers‚ Investigators‚+.

15 – DO-IT-YOURSELF: DIY Boat Building & Repair, DIY Boat Sales, DIY Boat Surveys, DIY Classes,+.

16 – MEDIA w/Creator Directory + Academy eLibrary: pDocs, Books, Magazines, Videos, Websites,+.

The above MAIN TOPICS and a more detailed listing of Subtopics

can be found on the Website Contents page and on the Right Sidebar.

An Alphabetical Index of the website can be accessed at Website Index.

What we have accomplished so far.

Anchors Aweigh Academy and its EverythingAboutBoats.org website.

- Published over 50,000 website pages about boats and boating, bringing us closer to reaching our goal of becoming "The ultimate reference resource about boats and ships for everyone from the beginning recreational boater to the seasoned professional mariner!"

- Published over 300 website main topic webpages, many with full articles on the topic. See our Website Contents or the Right Sidebar for the listing of the main topic pages.

- Published over 9,000 marine vendor webpages, all with their contact information, most with a description of their products and services, many with product documentation, specifications and independent reviews. (incl.: Boat designers, boat building tools, material and equipment manufacturers and suppliers, boat builders and dealers, yacht brokers, marine surveyors, boat insurers, boat transporters, skippers and crews, boatyards and marinas, yacht clubs, boat rentals and yacht charters, boating, seamanship and maritime schools, marine law attorneys and expert witnesses, boat refitters and repairers, book authors, magazine publishers, video producers, and website creators)

- Acquired over 120,000 pages of product documentation including Catalogs, Brochures, SpecSheets, Pictures, Serial Number Guides, Installation Manuals, OpManuals, Parts Catalogs, Parts Bulletins, Shop Manuals, Wiring Diagrams, Service Bulletins, and Recalls. And have made all viewable to Academy Members through our EAB website eLibrary.

- Acquired over 1,200 books and magazine back issues in our academy library and so far have made over 700 viewable to Academy Members through our EAB website eLibrary.

- Published over 500 DIY How-To articles about boat design, construction, inspection, operation, maintenance, troubleshooting and repair. We are working hard to do more.

We are currently formatting and polishing the Anchors Aweigh Academy online and hands-on courses. Our Marine Surveying course has proven to be excellent for both the beginner and the seasoned surveyor, and especially helpful to the Do-It-Yourselfer.

Current Academy Members must SIGN IN to gain FULL access to this

website including expanded pages and valuable Academy programs

like our Academy eLibrary and our Ask-An-Expert Program!

If your membership has expired, CLICK HERE to Renew.

IF YOU ARE NOT YET AN ANCHORS AWEIGH ACADEMY MEMBER,

CLICK HERE to discover how you can become a Member and gain FULL access to

thousands of expanded pages and articles, and dozens of excellent programs

WITH JUST A SMALL DONATION!

Comments for Public Viewing

Submit any comments for public viewing via email To: Comments♥EverthingAboutBoats.org (Replace "♥" with "@")

Please remember to put this webpage's title in the subject line of your email.

All comments are moderated before they appear on this page. See Comment Rules.

General Comments About the Website

FROM Donald: "This is an awesome website. I found the information that I needed right away from one of the over 20,000 free articles that you provide as a public service. I'm surprised that so much if this site is free. But I still signed up so I could access the thousands of expanded pages, interesting articles, and dozens of valuable programs! The member's library of books, magazines and videos that I can view online is really terrific! I understand that you and your staff are all unpaid volunteers. Please keep up the good work. And I commend you for your plans to add another 10,000 free informative articles over the next year. I'm thrilled to support you in this endeavor with my small membership donation. Thanks again for all your hard work."

FROM Huey: "I agree with my Uncle, I too have found the articles to be very enlightening. They say that it will take about 100,000 articles to cover the full scope that they have envisioned for the website. They have over 20,000 articles so far and that's doing pretty well, but it could take several years to get the rest. I also noticed that many of the Main Topic Pages and some of the article pages are still in the rough draft stage. I guess that they will fill in as they can get volunteers to work on them. But what I can't figure out is why anyone would spend the time writing informative in depth articles just to give away free to this website for publication? What's in it for them?"

FROM Dewey: "Well Huey, to me It looks like most of the articles on this website are written by very informed people, like boating instructors, boat designers, boat builders, riggers, electricians, fitters, marine repair technicians and marine surveyors. Writing such articles helps establish them as knowledgeable professionals. After all, this website was originally created by a school for marine technicians and marine surveyors. The website is growing in content every day. They even had to move to a bigger, more powerful server because the website's traffic has been growing exponentially."

FROM Louie: "I agree with everyone above. This site is quickly becoming the ultimate reference resource about every aspect of boats and ships for everyone from the beginning recreational boater to the seasoned professional mariner. I use the topic pages on the right sidebar to browse around the website. It's like a Junior Woodchucks' Guidebook for Boaters. Their Members' Library of over 300 popular and obscure books and over 200 magazine back issues that can be viewed online is fabulous. The Academy's magazine is especially informative. On top of that, there is the "Ask-An-Expert program for members where you can get an expert's answer to any of your boat questions. And a whole years membership is only $25. What a deal! I really love being part of this "Everything About Boats" community and help provide thousands of helpful articles free to the public. I think that I'll sit down right now and write an article about my experiences boating with my uncle."

FROM Scrooge: "You rave about this website like it was the best thing since sliced bread. Well, I think it stinks. Sure, it has a lot of good information for boaters, and they're adding more every day, but it will probably never be finished. Furthermore, I don't even own a boat. And I wouldn't have a boat even if someone gave me one. Boats are a waste of money and time and energy and money! They're just a hole in the water you pour money into. If you gave me a boat, I'd sell it quicker then you could say Baggywrinkle. Then I'd lock up the cash with all my other money so I could keep my eye on it and count it every day. Bah humbug."

FROM Daisy: "I'm just so glad that Donald got the boat so we and the boys could enjoy boating — together. And of course all of the girls, April, May, and June, love to be on the water too, especially when that is where the boys are. Oh poor Scrooge, boating is more fun then you could possibly imagine."

FROM Scrooge: "After seeing how much fun you all have on the water together, I regret that I didn't have that much fun when I was young. I've had a change of heart, and I'm giving each of you a Lifetime Academy Membership."

FROM Editor: "For those of you that have stayed with us this far, many thanks, and we hope that you found this little narrative informative. Your faithful support inspires us to keep working on this phenomenal website. We know that we have a lot more to do. Ultimately, we hope that we can help you enjoy the wonder filled world of boating as much as we do. We are all waiting to see what you have to say about this webpage article. Submit any comments via email To: Comments♥EverythingAboutBoats.org (Replace "♥" with "@"). Be sure to include this page's title in the subject line. Also, your corrections, updates, additions and suggestions are welcomed. Please submit them via email To: Editor♥EverythingAboutBoats.org (Replace "♥" with "@"). It has been truly amazing to see what we have been able to accomplished when we've worked together. Thanks to all those that have donated their valuable time and energy, and a special THANK YOU to all that have supported this cause with their membership donations."

Comments About This Particular Page

FROM ΞNameΞ: “Be_the_next_to_comment_about_this_page.” {230316}