PATH: HOME, ABOUT EAB, GLOSSARY, ASK AN EXPERT, WEBSITE INDEX, WEBSITE CONTENTS » ∨

∧ BOAT BUILDING & REFITTING » Boat Equipment » Propulsion » Engines » Detroit Diesel »

∧ DO-IT-YOURSELF » DIY Boat Building, Outfitting, Refitting & Repair, DIY Schools & Classes »

∧ MEDIA w/Creator Directory » Product Documentation, Books, Magazines, Videos, Websites »

PAGE CONTENTS: (click ⇒ to go to each section on this page)

⇒ Product Overview, Features, Vendors, Specifications, Years, Ratings,+.

⇒ ^ Product Documentation: Catalogs, Brochures, Ads, AdVids, SpecSheets, Manuals, Recalls,+.

⇒ ^ Related Resources: EAB Topics w/Directories, Vendors, Products: Media: Books, Websites,+.

⇒ Visit EAB's FEATURED ARTICLES Home Page to preview the vast scope of our website.

⇒ This Month's Top 20 Most Popular Articles on our EAB website.

⇒ Layout of the EverythingAboutBoats.org Website's Pages: Page Types, Contents, Topics,+.

⇒ What our nonprofit Anchors Aweigh Academy and its EAB website have accomplished.

⇒ Members must SIGN IN to gain access to Members Only areas of this website.

⇒ Become an Academy Member and gain access to additional pages and programs!

⇒ Comments: Submit To ⇒ Comments♥EverythingAboutBoats.org (Replace "♥" with "@").

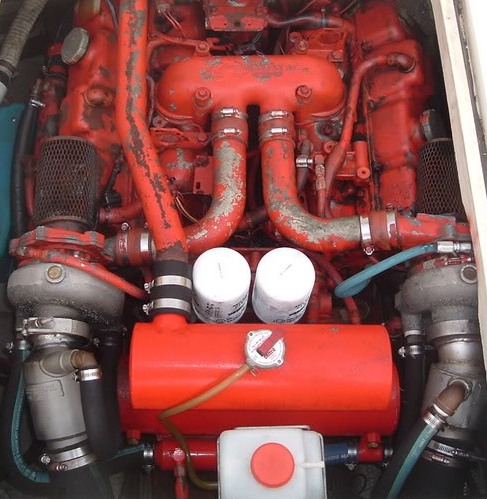

Detroit Diesel 8.2L “Fuel Pincher” marine engine “take-outs” with turbochargers but no charged air cooling.

DETROIT DIESEL 8.2 ARTICLE CONTENTS:

Detroit Diesel 8.2 Overview, Features,+.

Link to EAB’s Main Detroit Diesel Article with Contact Information, other products,+.

8.2 Serial Number Guide by Year.

8.2 Shortcomings.

How To Keep the 8.2 Alive.

What others have said about this engine.

Similar Engines from Major Competitors.

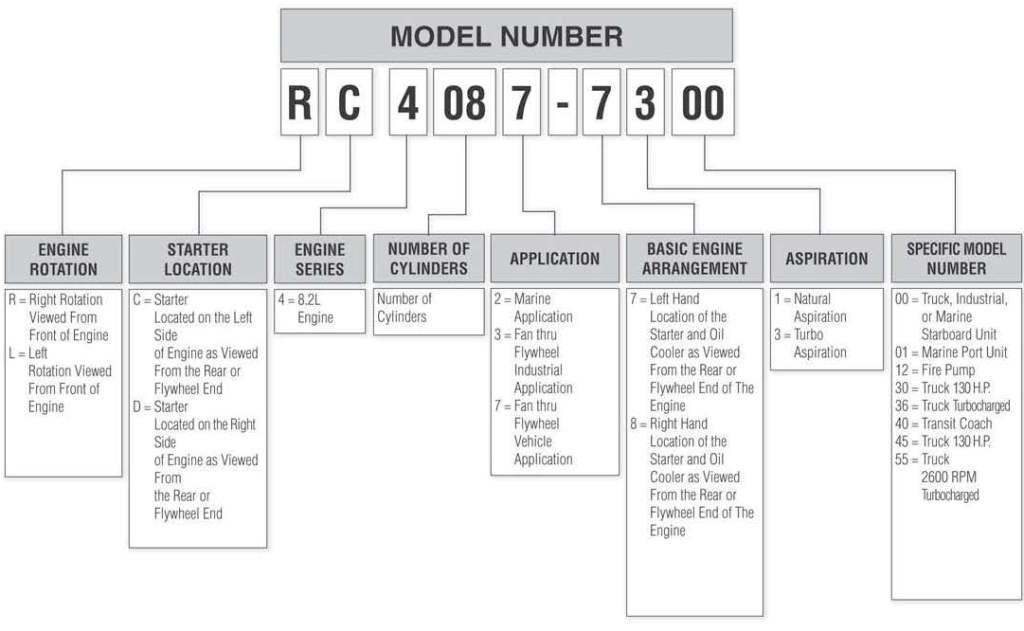

Identifying the 8.2 by Model Number on Options Label.

Detroit Diesel 8.2 Specifications, Years, Ratings,+.

Product Documentation: Catalogs, Brochures, SpecSheets, Manuals, Parts Lists. Recalls,+.

Detroit Diesel (DDC) had been building only 2-Stroke Cycle engines such as the venerable 6-71 since General Motors created the division in 1938. However, by the late 1970’s with the raising cost of gasoline and diesel and the inefficiencies inherent in their 2-Stroke Cycle engines (i.e. Roots blower used for scavenging the 2-Stroke Cycle air intake) which resulted in them consuming more diesel fuel than their competitors’ modern 4-Stroke Cycle engines, Detroit Diesel realized that for them to compete in the growing medium duty truck market, they needed a cheap, fuel efficient engine to power medium duty trucks and school buses. They developed a lightweight, slightly under-square (108mm bore x 112mm stroke) 500 cubic inch displacement, 4-Stroke Cycle V8 diesel engine called the 8.2 Liter “Fuel Pincher” which was introduced in GM trucks and buses for the 1980 model year.

The 8.2 or 8.2L (L standing for “Liter”) became the designator for the entire family of these 8.2 liter displacement engines, both naturally asperated and turbocharged. The model number 8.2T indicated that the model was turbocharged. The 8.2 was developed for the medium truck market that was dominated by gasoline engines and was therefore a much lighter duty engine then the 2-Stroke Cycle Detroit Diesel engines that dominated the heavy truck market during WW2 and post war years. The 8.2 was not developed as an interim replacement for the 2-Stroke Cycle Detroit Diesel heavy truck engines as it was much too small and lightly built. The 2-Stroke Cycle Detroit Diesel heavy truck engines were immediately succeeded by the 4-Stroke Cycle Detroit Diesel inline 6-cylinder 60 Series heavy truck engine series.

Several truck manufacturers including Ford, quickly embraced the 8.2 because of its low initial cost and high fuel economy especially when compared to the gasoline engines it was intended to compete with. However, the 8.2 quickly became known for its lack of power compared to the gasoline engines. Early naturally asperated models were rated at 165 horsepower which is only 1/3 horsepower per cubic inch of displacement, typical for a naturally asperated diesel engine. The 8.2’s relatively short stroke limited its torque and it became known for it’s sluggish acceleration. Surprisingly, In 1982, an even more sluggish 130 horsepower version was introduced.

Initially, DDC wisely chose to only lightly boost the turbocharged models, mainly for better performance at higher altitudes. The first was rated at only 205 horsepower at sea level, then came those rated to 230 horsepower, and then to 250 horsepower (an even 1/2 hp per cubic inch). Later turbocharged marine models with the larger head bolts and better head gaskets were fitted with intercoolers to attain a more “respectable” 300 hp.

Unfortunately, all models succumbed to high failure rates due to the engine’s inherent shortcomings with the higher output models exhibiting the quickest failures. These shortcomings will be described in detail later in this article. In spite of these shortcomings, the 8.2 was marinized by DDC and a few third-party companies including Covington Diesel, Johnson & Towers. and Stewart & Stevenson. The latter marinized one version (pictured below) with two small Turbos and no charged-air cooling (i.e. intercoolers/aftercoolers).

Detroit Diesel 8.2L engine marinized by Stewart & Stevenson with twin turbos but no charged-air cooling.

Note the pressure cap on the engine coolant reservoir and the coolant return tank.

See the section on “How To Keep the 8.2 Alive“.

Was the Detroit Diesel “Fuel Pincher” as bad as some say?

“Unfortunately for consumers, there is a lot of misinformation in the marketplace about this engine. Be sure to read this entire article to get the real facts so you can make truly educated decisions.”

Was the Detroit Diesel “Fuel Pincher” a Dieselized Gas Engine?

The 8.2 engine utilized several design features found in most automotive gasoline engines such as parent bore cylinders and short piston skirts. This in part led to the popular misconception that the 8.2 was an adaptation of an existing gasoline engine. While this is true of some other engines like the ill fated GM 5.7L V8 diesel engine adapted from the Oldsmobile 350ci V8 gasoline automobile engine and the GMC Toro-Flow Diesel engine adapted from the GMC V6-V8-V12 gasoline truck engine family, it is not actually true of the 8.2 which was a new design intended to be a medium-duty diesel engine from its inception. It was not, however, intended to be a heavy-duty engine like the other engines in the Detroit Diesel lineup that had dominated the heavy truck and bus markets for decades.

The 8.2 was not expected to achieve the million miles between overhauls of heavy truck engines, but it was expected to last more than 100,000 miles in medium-duty truck service. Unfortunately, due to its inherently weak “Open Deck” free-standing cylinder design and light build, the 8.2 could not reach these goals and proved to be quite troublesome especially in marine service as it was plagued by many of the same problems that dieselized gasoline engines experienced including “blown” head gaskets, broken crankshafts and “spun” bearings. The 8.2’s shortcomings that led to these frequent failures are discussed in detail later in this article.

Also be sure to read the comments at the end of this page about how GM moved production of the 8.2 from the Detroit Diesel-Allison Division to the Chevrolet-Pontiac-Canada Division when Roger Penske acquired Detroit Diesel from GM in 1988 because, as it is rumored, “he did not want anything to do with the 8.2”. This production move to an automobile division was necessitated by GM’s contractual obligations to continue providing 8.2 engines, otherwise GM would have probably ceased production of the 8.2 earlier. The 8.2’s move to an automotive division undoubtedly contributed to the mistaken belief that the 8.2 was a dieselized gasoline engine.

1990 was the last model year that the 8.2 was offered in any GM products. Ford and most other truck manufacturers who had been offering the 8.2, had already abandoned it. After 1990, 8.2 engine production quickly slowed to a trickle, ceasing completely by 1994 as shown in the Serial Number Guide below. Of the roughly 300,000 8.2s produced, nearly 100,000 (that’s half the roughly 200,000 engines sold) were built as “Spares” primarily to replace engines that failed within the engine’s warranty. The 8.2 failures cost GM’s Detroit Diesel division dearly.

Of the roughly 200,000 engines sold, nearly all failed while still under warranty, many catastrophically. Half of these were replaced by the complete engine “Spares” mentioned above, and the other half were repaired piecemeal. Many of the replacement engines have since failed more then once and many of the repaired engines have failed several times. Most all 8.2 engine failures can be traced back to the 8.2’s inherent shortcomings discussed in detail later in this article. Adding to this unfortunate situation, some repaired engines had been inadequately inspected (especially the cylinder blocks) and/or were poorly repaired and quickly failed again.

While most parts suppliers still provide common maintenance items like filters, only a few aftermarket parts suppliers still provide common “overhaul” parts such as gaskets, seals, pistons, rings and valves. Detroit Diesel and then GM, as well as most aftermarket sources, have discontinued nearly all parts and service support for the 8.2 including all hard parts (engine blocks, cylinder heads, camshafts, valve train components, crankshafts, connecting rods, oil pans, rocker covers, etc.). Service training, special tools and repair manuals have also been discontinued, making it very difficult for 8.2 owners to keep their orphaned engines running. Other developing problems for owners include the fact that fewer and fewer mechanics can be found that are knowledgeable and experienced with the 8.2, and more and more of those remaining mechanics that are, decline to work on them due to the 8.2’s irremediable failure rate.

The few 8.2s still operational today, especially in marine service, exemplify the beneficial effects that cautious operation and careful maintenance can have on these engines. See the two sections later in this article titled 8.2 Shortcomings and How To Keep the 8.2 Alive.

See our Detroit Diesel webpage for company Overview, History and Contact Information,

PLUS information about their other products.

NOTE THAT DETROIT DIESEL NO LONGER SUPPORTS THE 8.2L “FUEL PINCHER” ENGINE.

Detroit Diesel has not supported the 8.2 since 1988 when Roger Penske acquired Detroit Diesel from General Motors. GM’s support of the 8.2 has all but disappeared since.

Please do not try to contact any of the vendors on this website via our EverythingAboutBoats.org Phone, Email or Comment Systems. Your message will NOT be forwarded to the vendor.

Contact vendors directly (if still active).

Detroit Diesel 8.2L Engine Serial Number Guide

Serial Number Suffix = 8G

Total Engines Built = 300,000±

| Year MFR'd | Starting S# | Approximate Number of 8.2L Engines Manufactured |

|---|---|---|

| 1979 | 870 | 1‚510 (Full production started near the end of 1979) |

| 1980 | 2380 | 23‚934 (including 2‚000+ spares) |

| 1981 | 26314 | 23‚307 (including 3‚000+ spares) |

| 1982 | 49621 | 18‚105 (including 3‚000+ spares) |

| 1983 | 67726 | 22‚822 (including 4‚000+ spares) |

| 1984 | 90548 | 25‚097 (including 5‚000+ spares) |

| 1985 | 115645 | 30‚000 (including 10‚000+ spares) |

| 1986 | 145645 | 24‚274 (including 3‚000+ spares) |

| 1987 | 169919 | 24‚475 (including 5‚000+ spares) |

| 1988 | 194394 | 20‚163 (including 5‚000+ spares) |

| 1989 | 214557 | 16‚256 (including 5‚000+ spares) |

| 1990 | 230813 | 69‚197 (including 50‚000+ spares) |

| 1991 | 300010 | 124 (all spares‚ assembled from parts stocks) |

| 1992 | 300134 | 135 (all spares‚ assembled from parts stocks) |

| 1993 | 300269 | 150± (all spares‚ assembled from parts stocks) |

| NOTES: | Suffix = 8G | From Detroit Diesel Engine Serial Number Guides D#1‚ Dp#1‚ S#1. |

The several thousand complete engine spares produced each year, peaking at over 50,000 spares in 1990, is indicative of the extraordinarily high catastrophic failure rate of these engines. Additional cylinder head spares and engine block spares were also produced, reportedly as many as 100,000 each.

Detroit Diesel 8.2 Shortcomings

- The “Open Deck” cylinder block with free-standing cylinders allows uneven expansion of the cylinders that unevenly crushes the head gaskets. The “Open Deck” also allows excessive flexing of the cylinders that chaff the head gaskets. The crushing and the chaffing both seriously damage the head gaskets which inevitably leads to engine coolant leakage past the head gasket. As more engine coolant leaks out of the cooling system, the engine will develop hot spots in the cylinder heads that may not be detected by the engine instrumentation. And as more coolant leaks out of the cooling system, the engine will experience more serious overheat damage including warped and cracked cylinder heads, and scored pistons, rings and cylinders. However, an even more serious issue occurs later when the leakage of engine coolant into the combustion chamber(s) after the engine is shut down results in engine hydrolocking during engine restarting when cranking over the engine causes internal damage (see 4.b. below) that leads to catastrophic engine failure.

- Short piston skirts that result in rapid wear of pistons, rings and cylinders.

- A weak “bottom end” consisting of:

- Narrow crankshaft bearings (mains & connecting rods) that results in rapid bearing wear and failure.

- Thin crankshaft webs that fail due to reverse bending fatigue or snap when the engine hydrolocks due to shortcoming #1 above, which usually also causes twisting of the crankshaft, stretching of the crankshaft main bearing caps & mounting saddles, and compression bending of the connecting rod(s) .

These shortcomings are detailed below followed by suggestions on “How to keep the 8.2 alive“.

Detroit Diesel 8.2 Head Gasket Failures

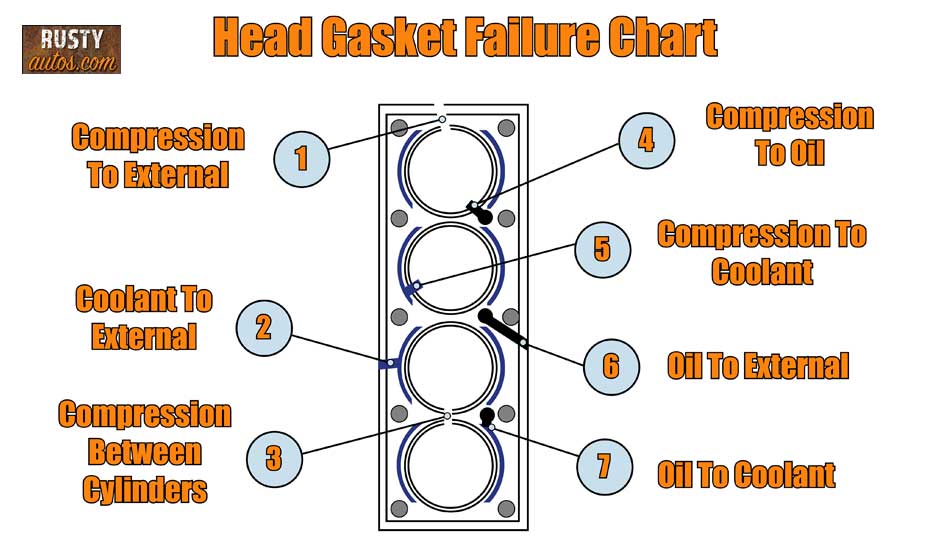

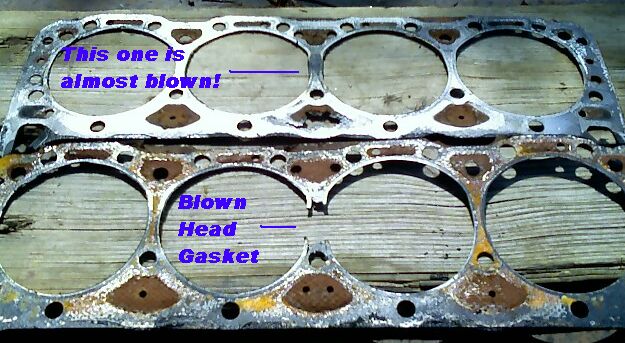

The chart above shows the Seven ways that a head gasket can fail. Failure number “3” is the most common head gasket failure experienced by most conventional “full-deck” engines and looks like the one below where the gasket failed between two middle adjacent cylinders.

This failure is typically the result of an engine overheat that warps the head enough to allow normal combustion pressures to leak past the gasket, eventually burning and blowing out the gasket allowing air to leak between the two cylinders.

The 8.2 head gaskets, however, usually fail in a different way and for a reason that is unique to the 8.2 “Open Deck free-standing” cylinder design.

The 8.2 usually suffers the number “5” head gasket failure in the chart above where coolant leaks into the combustion chamber past a head gasket that has been damaged by “Crushing” and/or “Chaffing”. This process will be discussed in detail later in this article. This is not the typical “Blown” head gasket failure number “2” shown above.

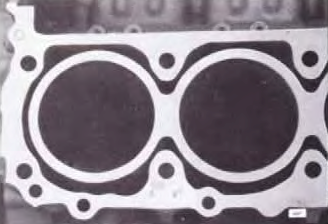

Early Detroit Diesel 8.2L Head Gasket that lacked the later reinforcement.

Early Detroit Diesel 8.2L Head Gasket that lacked the later reinforcement.

The “Crushing” and “Chaffing” that allows the 8.2 head gasket to leak coolant into the cylinder is caused by expansion and movement of the top end of the “free-standing” cylinder growing and working against the head gasket, damaging it enough for coolant to leak past the head gasket that is between the head and the sealing surface at the top end of the cylinder. The resulting breach allows the pressurized engine coolant to enter the cylinder during the intake stroke, then the compressing fresh air in the cylinder to blow into the cooling system during the compression stroke, and finally the combustion gases to blow into the cooling system during the power stroke and exhaust stroke. Additional engine coolant may enter the cylinder near the end of the exhaust stroke. Although rare, the breach may include engine oil passages and therefore allow cross-contamination of engine oil and coolant. The catastrophic results of “Hydrolocking” (which can occur when enough non-compressible liquid such as engine coolant has entered the cylinder to stop the piston before it reaches top-dead-center) are discussed in more detail later in this article.

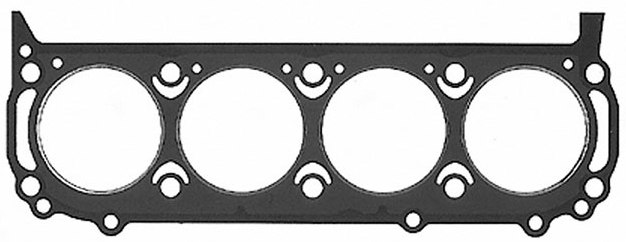

Later Detroit Diesel 8.2L Head Gasket with reinforced sealing surfaces around and between the cylinders.

Later Detroit Diesel 8.2L Head Gasket with reinforced sealing surfaces around and between the cylinders.

Back side of later Detroit Diesel 8.2L Head Gasket (Note that each head has only 10 head bolts).

Back side of later Detroit Diesel 8.2L Head Gasket (Note that each head has only 10 head bolts).

8.2 head gasket failures are often blamed on engine overheating,

but this is rarely the case.

While overheating has been the cause of head gasket failures in 8.2s on rare occasions such as when engine belts have broken or when coolant was lost due to a leaking coolant hose, water pump seals, etc. or in the case of marine engines, the raw water intake as been blocked or the raw water pump has failed, etc. this is rarely the case with the 8.2 head gasket failures. In most cases, the 8.2’s head gaskets fail first due to crushing and chaffing caused by the the “Open-Deck” free-standing cylinder design (which will be discussed shortly), then the loss of coolant due to the failed head gaskets leaking coolant leads to hot spots as the coolant level drops and ultimately to the engine overheating due to inadequate coolant, NOT the other way around. Unseen loss of ANY engine coolant strongly suggests that the head gaskets are already leaking coolant and need attention before the engine overheats or hydrolocks, causing serious damage like bent connecting rods, crankshaft bearing failure, etc.

It is also important to point out that any engine coolant that enters a cylinder can pass by the piston rings into the engine’s crankcase, contaminating the engine oil which can lead to other serious problems like failure of the engine bearings, etc. This is discussed later in this article.

It is often claimed that the inherent weaknesses that caused head gasket failures were remedied in later engines. This is not even close to being true. The later reinforced head gaskets and larger head bolts did make a slight improvement in head gasket longevity, but engines with these “improvements” still routinely suffer head gasket crushing, chaffing and failure. Preventing head gasket failure is more a matter of proper maintenance and cautious operation as discussed in “How to Keep the 8.2 Alive” found later in this article.

When the Detroit Diesel 8.2L is compared with other diesel engines, the reasons for the 8.2L head gasket failures become clearly obvious.

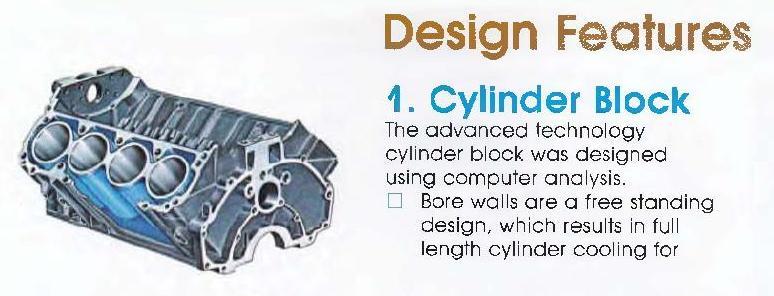

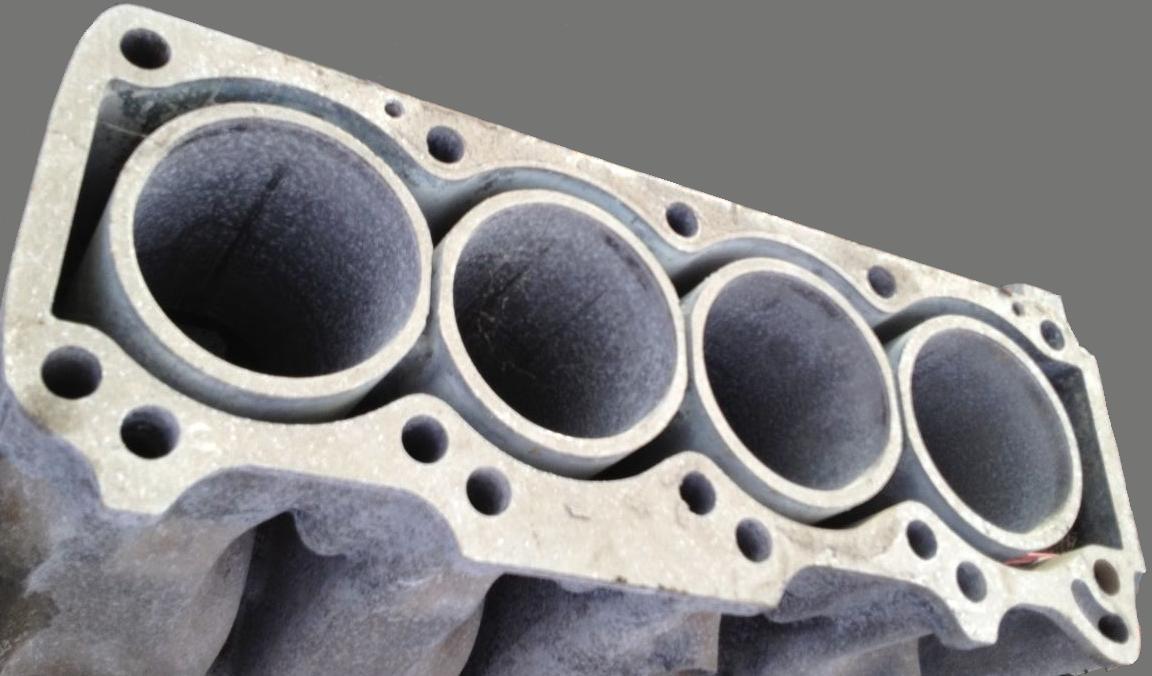

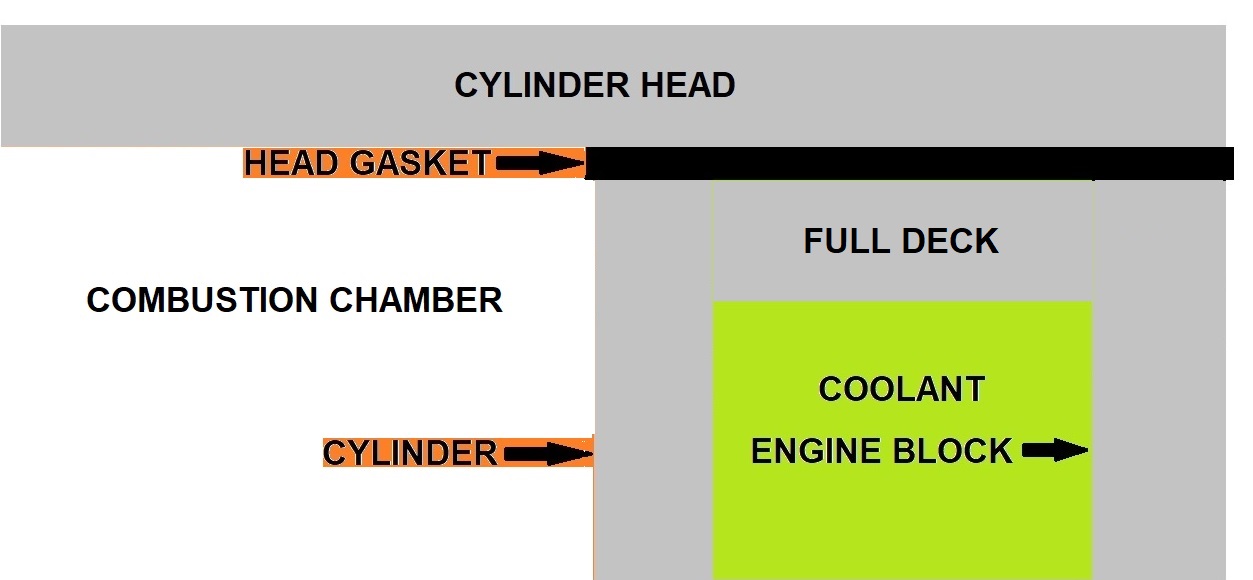

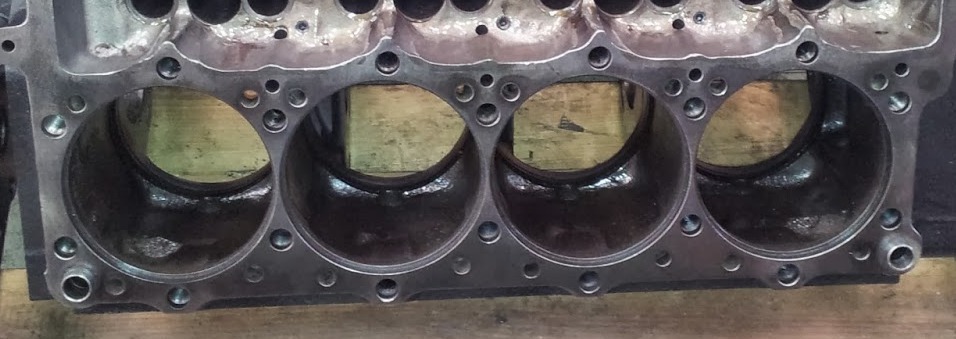

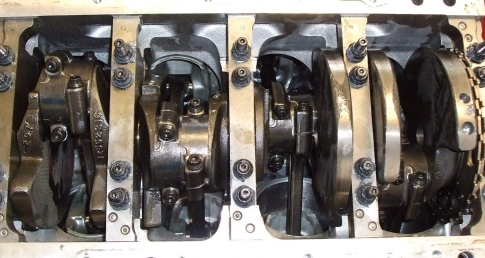

Detroit Diesel 8.2 “Open Deck” Free Standing Cylinders

Compare the 8.2s “Open Deck” Free Standing Cylinder design above with other diesel engines. Typical diesel engine blocks have cast and machined “decks” that support the top of the cylinders and evenly squash the head gaskets against the heads when the head bolts are tightened. In addition, most diesel engines have at least 6 head bolts (some shared with neighboring cylinders) in a full circle pattern around the top of the cylinder to more evenly provide the necessary head tightness on the head gasket. Both of these features can be seen in the Caterpillar 3208 whose V-8 cylinder block shown directly below was produced with 18 head bolts per head (almost twice as many as the 8.2) and a “full deck” that naturally supports the top of each cylinder, preventing the cylinders from growing from thermal expansion and crushing the head gasket and/or flexing and chaffing by working against the head gasket, damaging the head gasket.

Caterpillar 3208 “Parent Bore” V-8 Cylinder Block with Full “Deck” and 18 Head Bolts per Head.

Unfortunately, the cheaper Detroit Diesel 8.2 engine block, as clearly seen in the second picture above and illustrated in their “8,2L Advantages” brochure shown directly below, has neither the “full-deck” nor at least six head bolts per cylinder. The 8.2 has only 4 head bolts per cylinder and most of those head bolts are shared with neighboring cylinders for a total of only ten head bolts per four cylinder head.

Detroit Diesel 8.2L Block with “Free Standing Cylinders” (Note the open cooling jackets around the cylinders)

This brochure is available for viewing in its entirety by Academy Members as a PDF from our Academy eLibrary – Click Here – where all can see a scathing review of this brochure.

According to the above cited brochure, the Detroit Diesel 8.2 cylinder block was “designed using computer analysis” (Remember the old adage “Garbage in, garbage out.”), and was cast without the full head gasket mating surface (the “deck”) leaving the joined “Siamese” cylinders “free-standing”. The 8.2 head gasket mating surface is drastically reduced and consists of just the narrow top ends of the cylinders which consequently, can provide only limited head gasket sealing surface that has proven to be woefully inadequate. Detroit Diesel advertised that the reason that they chose this design was to provide “full length cylinder cooling”. While this design does provide slightly more even cooling of the cylinders, the far more compelling reason to use this design was to leave the top of the cylinder casting open and accessible to allow a more precise locating of the mold (or die) during the casting process which allowed the block to be cast thinner and consequently lighter and cheaper as it did not require as much safety margin thickness for “mold slip”.

This “Open Deck free-standing” cylinder design is not new, nor is it exclusive to the 8.2, although rare with cast iron blocks, especially high compression diesel engine blocks. Most die cast aluminum blocks are of this design including most outboard boat motors and the ill-fated Chevrolet Vega car engine block pictured directly below, which also suffered from frequent head gasket failures that can be attributed to this “Open Deck” free-standing cylinder design.

Chevrolet Vega Gasoline Engine Block with “Open Deck” Free-Standing Cylinder Design.

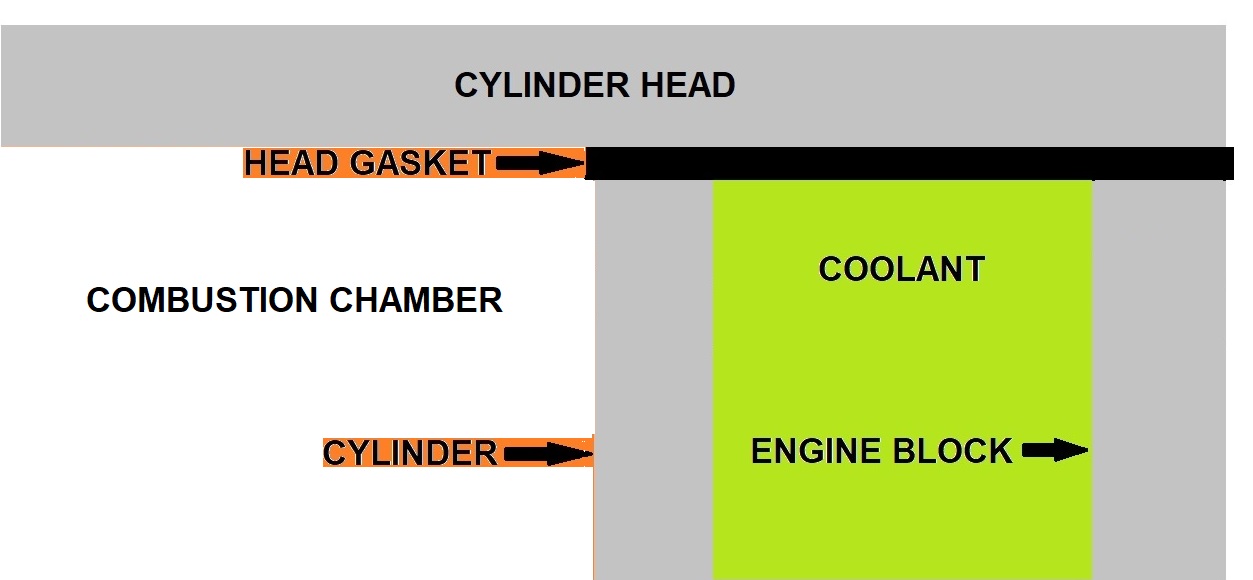

The 8.2 head gasket itself (see picture 6th above) was redesigned and made stronger (see pictures 4th & 5th above) to help accommodate the “open deck” design, which helped only slightly. Unfortunately, some aftermarket head gaskets are inferior and as a consequence more prone to failure. Fortunately, these weaker head gaskets can usually be discerned by visual comparison to the later, stronger genuine GM gasket. These head gaskets must be both strong and flexible so they can bounce back from being crushed by the expanding cylinders* without being broken up by the cylinders working back and forth**. Unfortunately, no effective method of stabilizing the cylinders in the block has proven effective such as filling the gap between the cylinders and the block with some type of material or joining them with a welded/brazen filler, webbing or pseudo-deck. The illustrations below show an engine with the “open deck” design and therefore lacks any physical connection between the cylinder and the engine block. The first illustration shows the condition of the head gasket before the engine is ever run and warmed up for the very first time.

1. Illustration of 8.2 Head, Head Gasket, Cylinder, and Engine Block when first Assembled.

1. Illustration of 8.2 Head, Head Gasket, Cylinder, and Engine Block when first Assembled.

*Metal expands when it is heated. The 8.2 unattached “Free Standing” cylinders run hotter then the exterior wall of the cylinder block as seen in the illustration below. Consequently, without a “full deck” joining the cylinder to the block to restrain the expansion of the cylinder, the 8.2 cylinders expand more then the block by a coefficient of thermal expansion of roughly 0.001% per °C difference between the temperature of the cylinder and the temperature of the engine block when warmed to running temperature, crushing the head gasket against the head. As illustrated below, a diesel engine running under normal load produces combustion gases of roughly 1150°F (461°C). During combustion and the piston’s power stroke, the cast iron cylinder can absorb enough of the heat energy to heat up over 550°F (188°C) on its inner bore surface. The outer surface of the cylinder is normally cooled to slightly under 300°F (149°C) by the engine’s coolant. The engine block’s outer wall absorbs some heat from the engine coolant and will therefore normally run at slightly below the temperature of the engine coolant as it looses some heat warming up the ambient air in the engine space. The temperature of the engine coolant is controlled by the engine’s thermostat and cooled by the heat exchanger.

2. Exaggerated Illustration of a running 8.2 engine where the cylinder has warmed up and expanded

2. Exaggerated Illustration of a running 8.2 engine where the cylinder has warmed up and expanded

more then the cooler outer walls of the engine block, crushing the head gasket against the head.

When the engine load is reduced or the engine is shut down as illustrated below, the cylinder cools and contracts, drawing back and away from the head gasket, leaving the head gasket much more likely to leak.

3. Exaggerated Illustration of the top of the cylinder drawing back away from the head gasket as the cylinder cools making the head gasket more likely to leak coolant into the cylinder’s combustion chamber.

3. Exaggerated Illustration of the top of the cylinder drawing back away from the head gasket as the cylinder cools making the head gasket more likely to leak coolant into the cylinder’s combustion chamber.

Unfortunately, each time that an “Open Deck free-standing” cylinder type engine is started cold, and warmed up to running temperature, the engine’s head gasket is crushed. And each time that the engine cools down after being shut off, the cylinder contracts and draws back away from the crushed gasket leaving the engine’s head gasket even more likely to leak coolant. Even the temperature difference that the cylinder experiences during light load running and heavy load running will cause some cylinder expansion and expose the head gasket to some crushing. Unfortunately, head gasket leakage due to this design shortcoming tends to become more likely with each warm up and cool down cycle the engine experiences.

When 8.2 head gasket failures proved to be such a chronic problem, larger head bolts were introduced in the production of later engines suggesting that the engine’s designers felt that the early 8.2’s head bolts were too small and weak to properly clamp the head gaskets tightly between the cylinder heads and the engine block, and therefore larger head bolts tightened to a higher torque would cure the problem. Later 8.2 head bolts were slightly larger in diameter (15mm vs 14mm) which allows for slightly higher head bolt torque (156 lb-ft vs 145 lb-ft). This was touted as a “vast improvement” and it was therefore recommended that all earlier 8.2 engines be retrofitted with the larger head bolts by re-drilling the heads and re-tapping the engine block. But, when the head gasket failure rate did not improve, they quickly realized that they had misdiagnosed the real cause for the failures (as described in detail above) and that the only real cure was to cast engine blocks with a “Full Deck” as described below.

An engine with a “Full Deck” that restrains the cylinder from expanding against the head gasket, cannot crush the head gasket like an engine with “Open-Deck Free-Standing” cylinders (see illustration below).

Illustration of an engine with a “Full-Deck” cylinder block design. The “Full Deck” prevents the cylinder from expanding and crushing the head gasket against the cylinder head. The “Full Deck” also prevents the cylinders from flexing and moving back and forth, side-to-side and chaffing the head gasket.

Illustration of an engine with a “Full-Deck” cylinder block design. The “Full Deck” prevents the cylinder from expanding and crushing the head gasket against the cylinder head. The “Full Deck” also prevents the cylinders from flexing and moving back and forth, side-to-side and chaffing the head gasket.

See Engine Head Gasket Wear for more details.

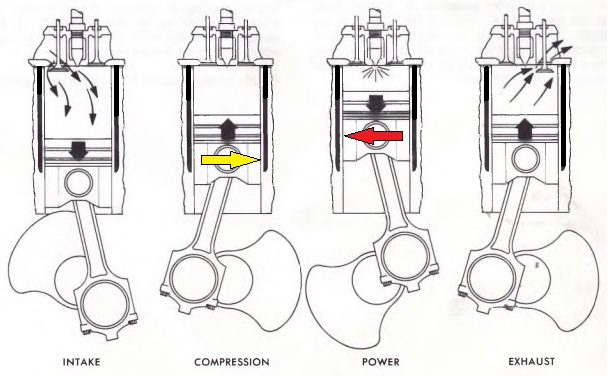

**Besides the drastically reduced head gasket sealing surface and the cylinder over-expanding and crushing the head gasket (see Open Deck Free-Standing Engine Cylinder Block Design), an even more destructive deficiency exists in the 8.2 due to the “Open-Deck Free-Standing Cylinder” design. Because the cylinders lack any connection between the tops of the cylinders and the engine block, there is nothing to support the top of the cylinders and prevent the cylinders from flexing and moving back and forth, side-to-side and working against (i.e. chaffing) the head gasket when the engine is running especially at higher power output. Chaffing of the head gasket is even more evident when the engine is boosted by turbocharging.

Exaggerated Illustration of an 8.2 engine with head gasket damage due to the cylinder flexing back and forth, side-to-side and chaffing the head gasket, making the head gasket more likely to leak coolant into the cylinder’s combustion chamber.

Exaggerated Illustration of an 8.2 engine with head gasket damage due to the cylinder flexing back and forth, side-to-side and chaffing the head gasket, making the head gasket more likely to leak coolant into the cylinder’s combustion chamber.

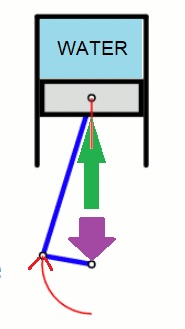

This “cylinder flexing” process is more thoroughly illustrated in the 4-Stroke Cycle diagram below where the piston can be seen first pushing against the right side of the cylinder during the compression stroke (see yellow arrow) and then pushing even harder against the left side of the cylinder during the power stroke (see red arrow). This ‘back and forth’ pushing force is of course due to the changing angle of the connecting rod to the crankshaft’s rod journal as the crankshaft turns. Without a full “deck” to support the tops of the cylinders, the cylinders are allowed to flex back-and-forth, moved by the side loads induced by the piston. A full deck would prevent the top end of the cylinder from chaffing against the head gasket. At low load, the chaffing may be only slight, bit at higher load the chaffing will be more severe. Predicting exactly when the gasket will start leaking is practically impossible. It is simply a matter of engine operational time before the chaffing damages the head gasket enough to result in substantial leakage. Obviously, gasket chaffing damage will occur more quickly if the engine misfires, detonates, or is lugged.

Without a “Full Deck” to prevent crushing and chaffing damage to the 8.2 head gasket, the gasket is unfortunately doomed to fail which will result in the ensuing leakage.

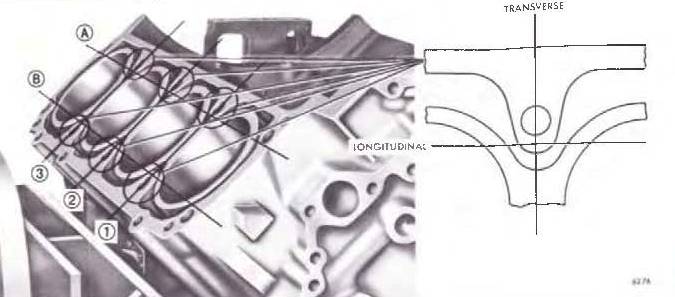

The Detroit Diesel 8.2L Service Manual #6SE421 describes in section 1.1 the procedure for checking the flatness of the top of the block with a straight edge after the head has been removed to determine if the block’s mating surface to the head (the “Firedeck”) is flat enough.

Detroit Diesel 8.2 Cylinder Block “Flatness Check” without the additional locations required later.

Additional transverse locations across cylinder centers were required by later revisions to this test procedure. Unfortunately, this test is very misleading if the head has already been milled flat after a previous test for flatness. multiple millings would obviously cause higher compression in the combustion chambers as more and more material is removed from the tops of the cylinders, effectively shortening the cylinder length & block height. If too much material is removed from the block, the pistons can even make contact with the cylinder head. A similar test performed with the pistons, rods and crankshaft installed can indicate how much the block has previously been milled. However, measuring from the top of the piston to the top of the cylinder will only be accurate if the crankshaft main bearing mountings are not stretched (elongated) from hydrolocking (discussed later in this article).

Checking the Cylinder Block’s “Firedeck” for Longitudinal Flatness using a “Straight Edge” and “Feeler Gauge”.

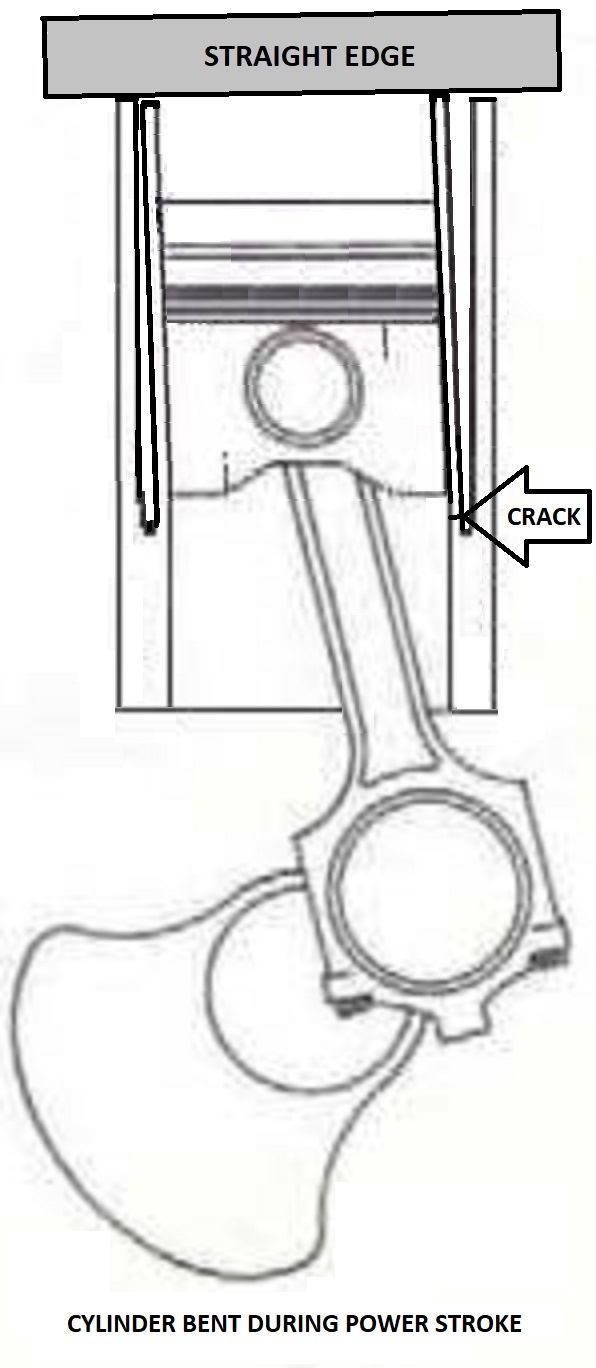

According to the manual, if the top surface varies by more then .07mm (0.003″) transversely or more then .17mm (0.007″) longitudinally, the block is NOT to be machined flat, but must be “rejected”. When checked, blocks from engines that had blown head gaskets were frequently found to be beyond these limits and therefore could not be reused, relegating them to the scrap heap. Amazingly, the cylinders in these blocks were often found to be slightly bent to one side (as illustrated below), undoubtedly by the force of the pistons during power strokes as illustrated by the yellow arrow above. These bent cylinders were often found to be out-of-round and sometimes even cracked at their base where they joined the block (see exaggerated illustration below). Any such cracking can allow coolant leakage directly into the crankcase.

Detroit Diesel 8.2 Cylinder Block Test Using Straight Edge.

The cylinder can also be bent to one side as described above by hydrolocking, which is very easy to distinguish as the cylinder would be bent the other way (to the right in the illustration above) as the piston is stopped by the liquid in the cylinder before top-dead-center during the compression stroke (with the crankshaft turning clockwise in the illustration above) instead of during the power stroke.

This “Open Deck free-standing” design makes the 8.2 engine prone to head gasket failures and the resulting internal hydrolocking damage (described later) which tends to be catastrophic. Operation of the 8.2 at flank (full) speed in marine service, especially those that are turbocharged, is not wise unless the propeller is “under-pitched”, allowing the engine to run more easily. This will also be discussed later in this article under “How to keep the 8.2 alive”.

NOTE: Although GM reportedly considered producing the 8.2 with a “Full Deck” when production was moved to GM’s automotive division in Canada, this plan unfortunately never came to fruition and the 8.2 was instead phased out of production.

The cylinder head must also be checked for flatness as they sometimes warp when overheated. They must also be checked for cracks and other damage that can result from overheating or hydrolocking. GM recommends that the smaller diameter head bolts be upgraded to the larger diameter head bolts. Before any head bolts are reused, they must be checked for signs of stretching damage, fatigue damage or thread deformation. They are often found to be unusable. The threads in the block should also be checked. If they are damaged, the block can often be salvaged by installing thread repair inserts such as Heli-Coils. However, cylinder blocks and heads of engines that have suffered damage to their head bolts and cylinder block threads have often suffered other stress related damage such as crankshaft main bearing cap, bolts and saddle stretching and cracking. and must be thoroughly examined for damage before considered for re-use. The main bearing bores should be checked. Any out-of-roundness indicates main bearing cap and/or saddle stretching deformation that makes the block unusable. This damage, the head bolts, and hydrolocking are discussed in greater detail a little later in this article.

SIDE NOTE: Engines with wet cylinder liners like the Cummins V-555 “Triple-Nickel” V8 engine shown below are typically cast with a “deck’ to hold the tops of the removable liners in place.

Cummins V-555 cylinder block with replaceable “wet” cylinder liners removed, exposing the cooling jackets.

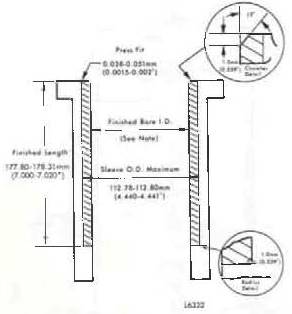

Parent Bore Cylinders & Repair Sleeves

Most diesel engine blocks are cast and machined to receive replaceable cylinder liners (either dry liners like some of the Ford-Lehman engines or wet liners like the Cummins V-555 V-8 diesel engine and the Cummins C series). The bore of these liners are usually machined to fit “standard” bore size pistons. If a “Linered” engine suffers excessive liner wear, or damage such as from overheat scoring or rust pitting, the liner is simply replaced. The 8.2’s cylinders, on the other hand, are cast and machined (e.g. bored and honed) directly into the engine block casting to fit “standard” bore size pistons. These are called “parent bore” or “native bore” cylinders.

Most gasoline automobile engines are “parent bore” engines as they are much cheaper to build. This is also the case in a few diesel engines such as the Cat 3208 and the Cummins B series. If a “parent bore” engine block has suffered excessive wear, or cylinder damage such as from overheat scoring or rust pitting, the cylinders can be bored and honed to fit oversized pistons. When the 8.2’s block is bored and honed for oversized pistons, the already weak unsupported cylinders are left even thinner and weaker, making cylinder flexing and head gasket failure even more likely. The boring also reduces the sealing surface that mates to the head gasket, increasing the probability of gasket failure. If the cylinders are too damaged to be bored to receive the largest oversized piston, Detroit Diesel suggests that the blocks can be reused by being bored and sleeved back to standard bore size by pressing in a repair sleeve. As illustrated below, the Detroit Diesel 8.2L Service Manual #6SE421 describes in the Shop Notes Section 1.0 (the 78th & 79th pages of the manual) the procedure for installing a repair sleeve in an 8.2 block.

Detroit Diesel 8.2 Repair Liner Installation per Manual.

In engines with thicker walled cylinders then the 8.2 and/or full decks, installing repair sleeves have been done very successfully. Unfortunately, engine rebuilders that have attempted to use repair sleeves in the 8.2’s cylinder bores have found that when the inherently weak “free standing” cylinder walls are machined oversized for these repair sleeves, the cylinder walls in the block become thinner and dangerously weaker, especially near the base of the cylinder where it joins the block, making the 8.2 cylinders more prone to flexing, and consequently even more likely to suffer head gasket failure (see next topic below) and more prone to cylinders cracking at their base. In the past, the best option was to simply replace the cylinder block. Unfortunately, new cylinder blocks are now virtually none existent as GM ceased production of the major castings long ago, and rebuildable used blocks are becoming very scarce. This shortage is compounded by many reusable automotive and marine 8.2 “take-outs” simply being scrapped without being checked for serviceability, as many consider the 8.2 not worth repairing. Occasionally, used 8.2s appear for sale, mostly on the internet, but after close examination they often prove to be too worn or damaged to be used in a rebuild. This all adds to the 8.2’s reputation as a “throw-away” engine.

Sometimes, when twin engines are replaced in a vessel, we find that while one of the engines is in serious trouble, whence the reason for the repower, the other engine may be serviceable or at least salvageable (if it was not overworked getting home). A proper engine survey and/or a very low price and shipping cost may reduce enough risk that acquiring such an engine may provide a viable option, or at least a temporary solution. Read on to learn more before you leap.

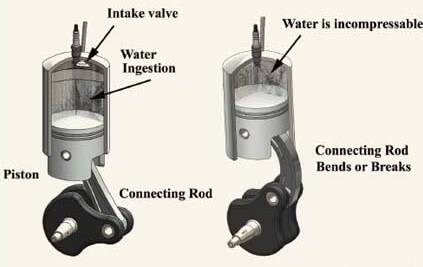

Hydrolocking

Hydrolocking may occur when an engine is submerged while running, however it most often occurs when engine coolant leaks into an engine’s combustion chamber after the engine is shut down and then the engine is later restarted with water in the cylinder. When the piston is stopped by uncompressible water in the cylinder before it reaches top-dead-center, the rotational energy of the cranking motor and the inertia of the rotating flywheel and crankshaft will often bend the connecting rod (as shown below). If the rod does not break outright, the bent rod will inevitably result in rod bearing failure and if not discovered, a “thrown-rod”.

The damage to two gasoline engine connecting rods can be clearly seen below. However, the 8.2 connecting rods tend to break rather then just bend because the 8.2’s short stroke requires the engine to be cranked faster, hence a more powerful cranking motor and bigger batteries.

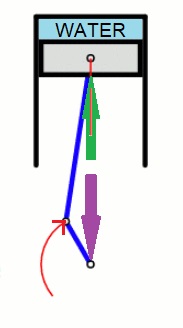

These incredible forces are due to the almost infinite leverage that the crankshaft can exert against the connecting rod when the piston is near top dead center. See illustration below. A little water in the cylinder can more easily damage the piston, wrist pin, connecting rod, rod bearings, crankshaft (by bending), crankshaft main bearings, main bearing caps, main bearing cap bolts, and main bearing saddles (last three by stretching) then a lot of water in the cylinder. However, a lot of water in the cylinder can more easily twist the crankshaft then a little water due to the leverage that the connecting rod can exert against the crankshaft due to the longer lever of the journal.

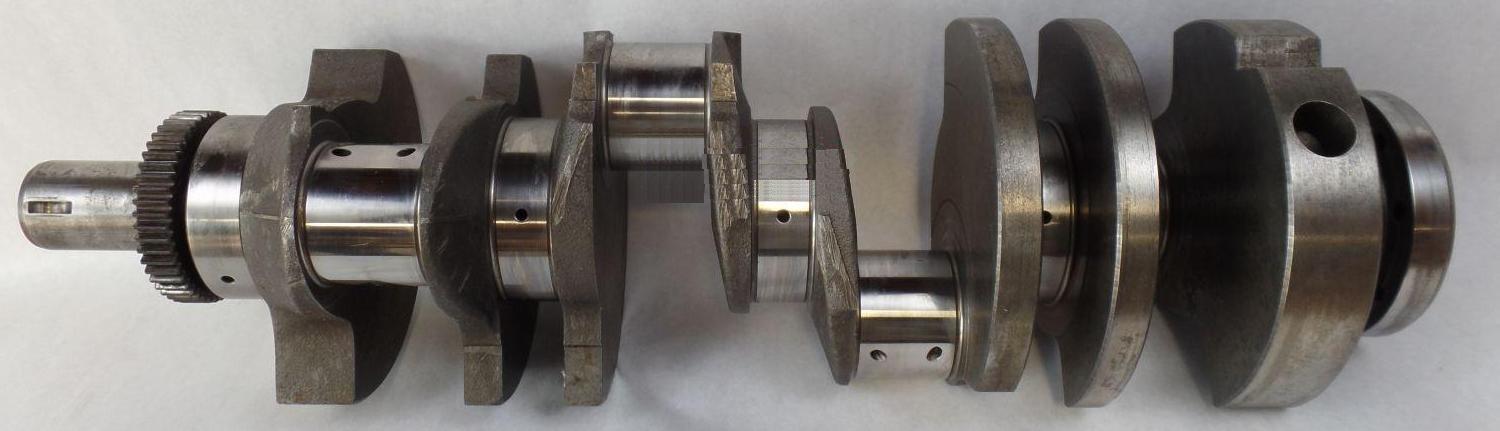

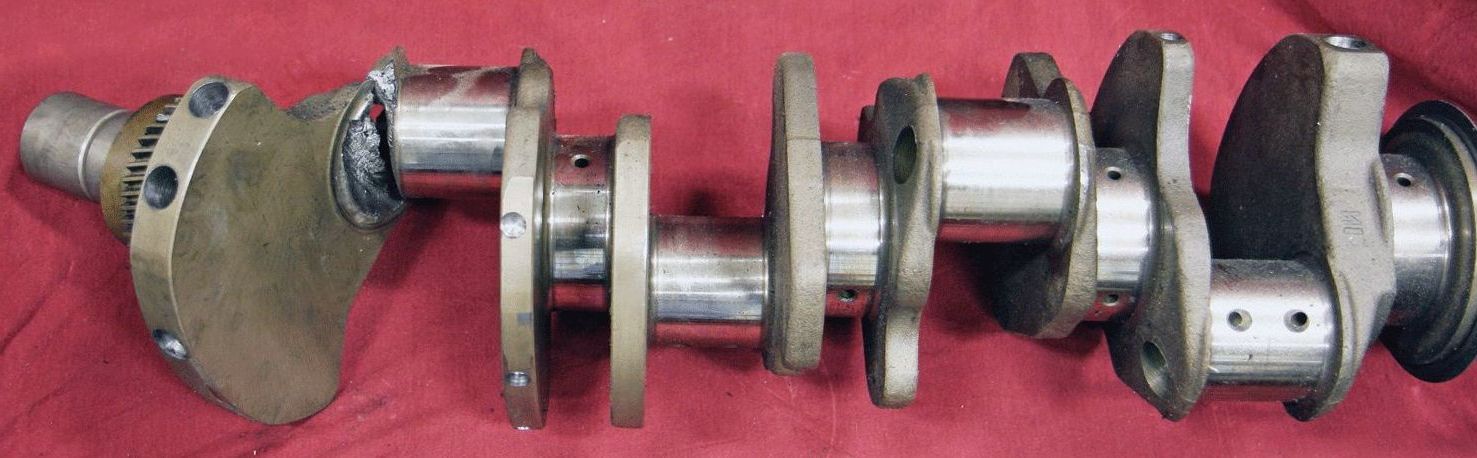

Damage that often goes undiscovered includes twisting of the crankshaft, stretching of the main bearing bolts and caps, and even cracking of the main bearing saddles in the block. Shown below is an 8.2 crankshaft that appears to be in good condition, but thorough inspection found it to be twisted from hydrolocking and therefore unusable. The main bearing bolts, caps, and saddles in the block were also found to be damaged enough that they were also unusable.

Twisted Detroit Diesel 8.2 Crankshaft

Few diesel engines can survive a hydrolock event during cranking without considerable internal engine damage, mainly because of the high torque cranking motors needed to start diesel engines due to their higher compression ratios compared to spark ignited engines.

Hint: If the crankshaft seems to slow down during a compression stroke more then usual while the engine is being turned over with the cranking motor, but then keeps turning, the engine may have just hydrolocked with a little liquid in the cylinder, and bent a connecting rod before continuing to turn. If the crankshaft stops completely while cranking, then it has probably hydrolocked with more liquid in the cylinder, stopping the piston before the crankshaft develops enough leverage against the rod to bend it enough to continue. See our webpage on hydrolocking for the complete description of this malady, its causes, consequences, and cures.

Detroit Diesel 8.2 Engine Block with Cylinder Head Removed showing Evidence of a “Leaking” Head Gasket.

In the case of the particular 8.2 engine pictured directly above with the head removed, the head gasket mating surface flatness test showed the surfaces far beyond the allowed limit because the “free-standing” cylinders had distorted out-of-round and were bent to one side inside the block. The engine shows evidence of engine coolant leaking past the “blown” head gasket and into the cylinders while the engine was running. “Water Washing” is the term coined by this author to describe the effect that the coolant water has on the surfaces of the combustion chambers (including the top of the pistons) when water (such as from leaking antifreeze) is introduced into the combustion chamber of an engine while it is running. Any carbon buildup on the metal surfaces is literally “steam-cleaned” off, even down to bare metal, by the water in the leaked coolant turning into steam due to the heat from combustion. The “Water Washing” pattern typically originates at the water’s point of entry (such as a head gasket leak or cracked head) and spreads from there across the combustion chamber surface. This effect can be seen to varying degrees on the tops of the pistons in the 8.2 pictured above, especially the far right piston where shiny metal (devoid of soot) can be seen near the edge of the piston crown.

When the “block height” (or what could be called the “deck height”) was measured, this block proved to have been resurfaced previous to this failure. A consequence of resurfacing can be an increase of the compression in the cylinders which exacerbates the gasket “chaffing” problem.

Like many other 8.2 engines, hydrolocking made this particular 8.2 engine shown above unrebuildable. Thorough examination should reveal whether or not a block is too damaged to rebuild. Unfortunately, many engines that are so damaged that they are unrebuildable have been rebuilt anyway and have consequently suffered early, if not immediate, failure.

A word about hydrolocking.

It is nearly impossible for an engine to ingest enough water into the cylinders through a blown head gasket while it is running to hydrolock the engine, as such little water will simply form steam during the power stroke and exit through the exhaust port during the exhaust stroke. Consider the huge amount of water that a vehicle engine will ingest when being driven in a rainstorm. Gallons upon gallons are ingested, and the engine simply runs smoother and quieter, AND produces more power and faster acceleration because the water turns to steam which helps push the pistons through the power stroke. This is a well known phenomena that was exploited by aircraft engine producers during World War II when they fitted “Water Injection” systems to their engines that sprayed water into the engine’s air intake while the engine is running. Alcohol was usually added to the water to prevent the water from freezing at higher altitudes where the air was colder. The net affect was an up to 50% increase in power and performance. Many P-51s were so equipped as were many other aircraft. Later, the Rolls-Royce aircraft engines that powered unlimited hydroplanes were often fitted with “Water Injection” systems to increase their performance. “Water Injection” is not uncommon for high performance engines, such as racing engines. Even early jet aircraft engines were fitted with “Water Injection” to improve their performance.

About the only time that an engine can hydrolock while running is when its air intake is submerged under water such as when a vessel experiences a swamping or sinking.

However, if engine coolant continues to leak into the cylinder(s) through a leaky head gasket, cracked head, porous cylinder or cracked cylinder after the engine is shut-down as in the case of the above 8.2 engine, and then the engine is cranked by the starter motor with coolant in the cylinder(s), the risk of hydrolocking of the piston(s) and damage to the connecting rod(s), crankshaft, etc. is almost always inevitable. In the case of the 8.2, the cylinder(s) will likely be bent as mentioned before and the crankshaft will likely suffer twisting damage and may break. And the crankshaft main bearing caps, bolts and saddles may suffer stretching and cracking damage from the extremely high loads on the already weak “bottom end”.

Many of the 8.2s’ bottom end failures are the result of hydrolocking (the result of

leaking head gaskets) that had bent connecting rods, stretched

main bearing mountings, twisted crankshafts, etc.

Due to the above mentioned inherent (and unfixable) shortcomings, most experienced mechanics consider rebuilding an 8.2 to be unwise and many veteran rebuilders simply refuse to rebuild them for fear of inevitable and early re-failure.

How Piston Skirt Length Affects Engine Service Life

There is a direct relationship between the length of the piston skirt and the length of the engine’s service life. The shorter the piston skirt, the greater the wear experienced by the pistons, the rings and the cylinder bores. As shown in the 4-Stroke Cycle diagram above, the piston is forced against the side of the cylinder (yellow arrows) by the angle of the connecting rod to the crankshaft rod journal. Generally, the less lubricated surface that the piston can provide against the cylinder, the greater the wear will be on the components. Also, the shorter the piston skirt, the greater the tendency for the piston to cock in the cylinder bore resulting in greater uneven wear. High compression engines, especially diesel engines, should have longer piston skirts to endure the higher side loads on the pistons and cylinders.

Compare the length of the short-lifed 8.2 piston skirt shown below middle with the long-lifed Caterpillar 7N4515 piston skirt shown below right. Longer life engines typically have piston skirts at least as long as the cylinder bore diameter. The 8.2 engine has short piston skirts that results in a shorter engine service life. See How Piston Skirt Length Affects Engine Service Life. The 350ci 5.7L Chevy small block V8 piston shown below left has an even shorter piston skirt. This gasoline engine piston would not survive the stress of a diesel engine’s compression, etc.

350ci Chevy V8 Short-Lifed 8.2 Long-Lifed Cat ·

Also note how the contact surfaces of the Chevy piston skirt and the 8.2 piston skirt have been further reduced by being squared-off around the wrist pin boss to make the piston lighter. The skirts are also cut-away to provide clearance for the rotating crankshafts when the pistons are near bottom-dead-center (BDC) which allows for short connecting rods. The 8.2 was designed with short, cut-away piston skirts and short connecting rods so the cylinders could be shorter and thus the engine’s overall height could be less, allowing it to fit into more limited-height applications. This also made the engine lighter and cheaper to build. As a consequence, the 8.2 has a much shorter expected service life then other engines with longer piston skirts. However, because of the 8.2’s other shortcomings, the 8.2 rarely survives long enough to actually “wear out”.

Other Piston Shortcomings

Also compare the distance from the crown of the piston to the first compression ring on the 8.2 piston to that of the Caterpillar piston. The distance is much less on the 8.2 piston which makes the 8.2 piston and rings much more vulnerable to damage from engine overheating, thermal runaway, and detonation then the Caterpillar piston. Note the wear and damage to the 8.2 piston, especially between the top ring and the top of the piston. This picture is found in the 8.2 brochure shown earlier. This brochure claims that “As you can see, these parts remained in like-new condition, showing little or no wear. In fact, they actually miked within new part specifications.” They went on make life projections of several engine components. But do these projections take into account the RATE OF WEAR? The brochure does not make mention of any initial pre-build micrometer measurements. Without these initial measurements, no valid projections can be made. The specifications are a range. If the component was measured to be at one end of the range when first installed and is now found to be at the other end of the range at 3,000 hours, the rate of wear would be considered very high and the life expectancy very low. Unlike the brochure’s claim that “the piston itself is projected to live 30,000 hours.” the shown piston (at 3,000 hours) is so badly worn and damaged that it is no longer usable due to metal transfer, scuffing and scoring. This is also true of the piston rings, connecting rod bearings crankshaft main bearings and several other components clearly shown in the brochure. No competent mechanic would reassemble this engine with any of these badly worn and damaged components.

Detroit Diesel 8.2 Crankshaft and Bearing Failures

The 8.2 engine below has “thrown” the #4 connecting rod through the cylinder block and oil pan near the surfaces where they join, punching holes in both. In this case, “Hydrolocking” damage to the inherently “weak bottom end” due to a coolant leak into a cylinder from a blown head gasket as discussed earlier was determined to be the root cause for this failure.

Detroit Diesel 8.2 with #4 rod thrown thru the ↑cylinder↑ block and the oil pan. Oil pan has been removed.

Unfortunately, the 8.2 also suffers from a “weak bottom end”. “Hydrolocking” can result in serious damage to the 8.2 connecting rods, crankshaft, bearings and bearing saddles in the cylinder block. However, the occurrence of “broken cranks”, “spun bearings” and “thrown rods” NOT caused by “Hydrolocking” are far too frequent. These issues are however, not uncommon of most smaller “V” cylinder configuration high compression engines, especially those with cylinder bores less then 5 inches (127mm) and is due to the overall shortness of the crankshaft.

“V8” Rod Bearings.

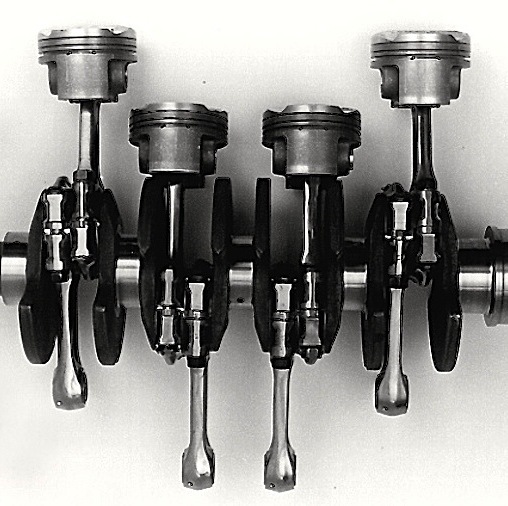

Compare the narrow width of the small V8 connecting rod bearings above with the wider width of a small inline 4-cylinder engine’s bearings pictured below which are nearly twice as wide.

“Inline-4” Rod Bearings.

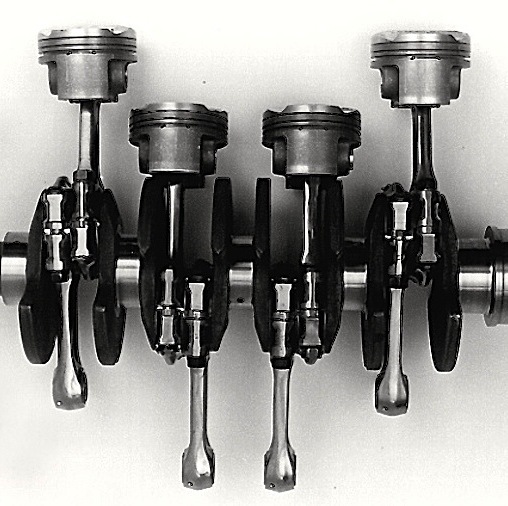

With twice as many pistons connected to a V8 crankshaft which is often not much longer then an inline 4-cylinder crankshaft of the same bore, there just isn’t much room for the connecting rod bearings, the crankshaft main bearings, and the crank webs. Note how narrow the crank webs, counter-weights, main bearings and connecting rod bearings have to be to fit on the short 8.2 crankshaft shown below. In the picture, the pistons and connecting rods for one bank have been removed and the narrowness of the rod bearing surfaces on the crankshaft can be clearly seen. The connecting rod bearings and crankshaft show serious wear and scoring, indicating imminent rod bearing failure. Also note the discoloration of the crankcase indicating that the crankshaft, bearings, etc. have been running hot, especially the crankshaft’s darkened front main bearing cap (at the left end of picture ) indicating that the bearing has overheated and has failed. This front main bearing failed due to a slightly twisted and bent crankshaft near the #2 main bearing that resulted from a #2 piston hydrolock caused by a blown head gasket. Narrow bearings are far more susceptible to damage and failure then wide bearings. Engine oil analysis tipped-off the prospective buyer to this engine’s internal damage and imminent demise.

Crowded Detroit Diesel 8.2 Crankcase with damaged rod bearings and overheated front main bearing (left).

Unfortunately, in the case of “slip-bearings” commonly used in 4-Stroke Cycle engines including the 8.2 crankshaft bearings, the narrower the bearings, the more difficult it is maintain an adequate lubricating oil film between the crankshaft’s steel surface and the softer metal surface of the bearing shell as the oil is more quickly squeezed out of the narrower bearings by the heavy loads of a high compression diesel engine especially at higher RPM’s. In the V8 crankcase pictured below with the connecting rod cap removed, see how narrow the rod bearing has to be in order to clear the radius cut on the shoulder of the crankshaft’s journal (red arrow). The broad radius helps prevent the crankshaft from cracking at the transition from the horizontal journal bearing surface to the vertical journal shoulder.

V8 Crankshaft and Connecting Rod with the narrow rod bearing highlighted in red.

Without an adequate oil film to keep the metal surfaces of the crankshaft and bearings properly separated, they will suffer erosion of the metal surfaces or worse yet make contact with each other causing metal transfer and scoring the surfaces, making bearing failure imminent. This damage can be clearly seen on the bearing shell shown below that was removed from the engine pictured second above. The soft lead/aluminum based overlay has been abraded enough to start exposing the copper based underlay which makes catastrophic failure of this bearing imminent. Note that the wear is slightly more pronounced on one side of the bearing (towards bottom of picture) suggesting that the connecting rod is slightly bent. When checked, the rod did prove to be slightly bent, probably by hydrolocking of the piston sometime in the immediate past. It is not uncommon for an engine to suffer this damage after a blown head gasket causes Hydrolocking. If an engine has suffered this hydrolocking damage after a blown head gasket, and this damage is not discovered and just the head gasket is replaced, the engine is obviously doomed to imminent catastrophic bottom end failure.

Detroit Diesel 8.2 Bearing showing serious scoring damage.

An engine oil analysis indicating elevated glycol, lead, copper and iron would predict a failure from hydrolocking bottom end damage, which in an 8.2 usually originates from a blown head gasket. It is also important to note that head gasket failures often drive coolant into the engine’s crankcase, contaminating the engine oil which can lead to failure of the engine bearings as well as other serious problems.

These narrow bearings are also more susceptible to damage from coolant contaminated or fuel deluded engine oil. Fuel from a leaky injector, injection pump, or fuel lift pump that enters the oil sump and deludes the engine oil will thin the oil so that it cannot maintain an adequate film between the metal parts and a bottom end failure will ensue. An engine oil analysis indicating elevated levels of fuel, lead, copper and iron would indicate bearing damage from fuel deluded engine oil.

A crowded crankshaft: Even though the connecting rod pins on a V8 crankshaft are the widest journals on the crank, when assembled the V8 crank will have two connecting rods crowded onto each rod journal leaving little room for each individual rod bearing.

V8 Crankshaft with Two Rods assembled to each rod Journal.

In the picture third above and the illustration below, it is easy to see how narrow the rod bearings of an 8.2 have to be. Note the two oil feed holes per rod journal (one for each connecting rod. In a fully pressurized lubrication system like the 8.2 has, the oil is fed to the center of each bearing so that it can form a lubricating film of oil between the crankshaft journal and the bearing surfaces, as it works its way to the outer edges of the bearing where it squirts out. The narrow width of the bearings and the resulting increased load on the oil, forces the oil to squirt out of the narrow bearings much more quickly then with the wider bearings.

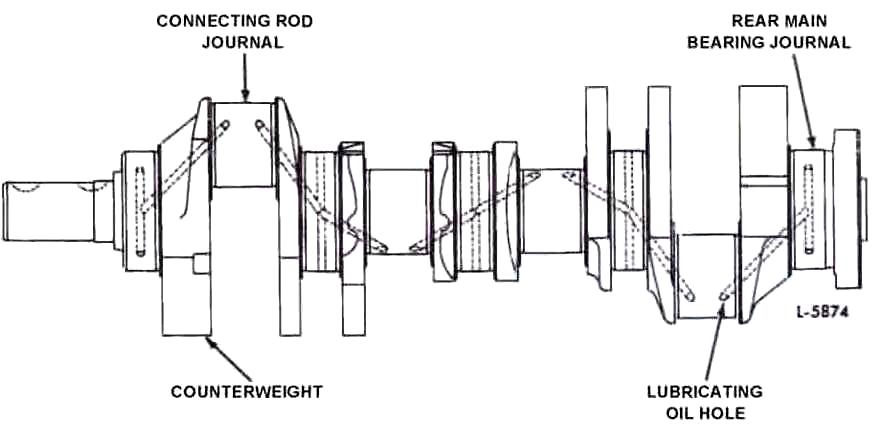

Detroit Diesel 8.2 Crankshaft – Illustration.

The larger the cylinder bores, the longer the crankshaft and therefore the more room available for wider bearings. “V” Pattern engines such as V8 engines with cylinder bores larger then 6″ typically have plenty of room on the longer crankshaft for bearings wide enough and crank webs strong enough to allow the engine to produce very high output, even well over one horsepower per cubic inch of displacement.

Unfortunately, for the 8.2 the typical crankshaft wear is far greater then the wear found on better engines. The Detroit Diesel 8.2 Service Manual 1985 contains the recommended procedure (see Section 1.3 Crankshaft) for resurfacing “typical Ridging of Crankshaft” as much as .025mm (0.001″) using emery cloth and then crocus cloth. This rather crude Do-it-yourself procedure can easily result in very poor bearing journal surfaces that can cause early bearing failure. A qualified crankshaft machinist with the proper equipment able to perform quality resurfacing has the best chance of providing a satisfactory bearing journal surface.

On the 8.2 crankshaft pictured five above and then illustration directly above, note how narrow the five main bearing journals are especially when compared with the 4-cylinder crankshaft shown second below. Crankshaft main bearings will be discussed in more detail a little later.

Another issue with any small V8 crankshaft is the narrow crank webs which are much weaker and consequently much more prone to bending, cracking and breaking as shown below.

V8 Crankshaft with broken web near front end of crankshaft (left).

By comparison, the inline 4-cylinder crankshaft below which will have only one rod fitted per journal when assembled will have much wider rod bearings. Note the much wider main bearing journals which will accommodate much wider main bearings. Also note the wider and much stronger crank webs between the bearing journals. This crankshaft is from a 212 cubic inch displacement engine, which is less then half the displacement of the 500 cubic inch 8.2 engine.

Detroit Diesel 4-53 4-cylinder 2-Stroke Cycle crankshaft.

The inline 4-cylinder crankshaft shown above has 5 main bearings. The crank webs, and the width and diameter of the main and rod bearings have been optimized to carry the stress and load of a high compression, high output engine. By comparison, the V8 crankshaft has the same number of main bearings for twice as many cylinders, and the V8 main bearing journals are much narrower. You can see how crowded a small V8 crankcase can be in the picture directly below. There just isn’t enough room for rod bearings or main bearings to be wide enough to carry the heavy loads generated by a high speed, high compression, high output engine.

Narrow main bearings, main bearing caps and main bearing saddles in the cylinder block cannot support the crankshaft as well as wider and stronger components can. Rapid bearing wear and stretching of the caps, bolts and saddles are common in these high compression engines, and have proven even more susceptible to “Hydrolocking” damage.

Notice that the main bearing journals of the V8 crankshafts shown in the illustration and pictures above have been increased in diameter to increase the bearing surface in an effort to compensate for their narrowness. But at some point this becomes counter-productive because the increased diameter increases the slip-bearing surface speed which makes it more difficult for the oil to maintain adequate oil film thickness at higher RPM’s. By comparison, a 4-cylinder crank’s main bearings can be wider so they can more easily maintain oil film thickness and carry the loads, hence the journals can be smaller in diameter to reduce bearing surface speed. This is why inline engines with the wider bearings, stronger crank webs, and main bearings between each cylinder, can be air charged (e.g. with a turbocharger) to reliably produce more than twice the horsepower per inch of displacement then a small V8 like the 8.2. Air-charging these stronger inline diesel engines can also enable them to run cleaner with fewer emissions as explained in our articles Fuel Fundamentals and Selecting the Right Diesel Engine for Your Boat.

The 8,2’s Short Stroke

Engines with longer piston strokes have the advantage of typically producing much higher torque at slower crankshaft speeds (RPMs). The 8.2 was designed with a stroke much shorter then most other diesel engines of this displacement. It is just slightly “under-square” with a 108mm bore × 112mm stroke. Besides allowing the engine height to be lower, the shorter stroke also has the advantage of reducing the load on the crankshaft main bearings, however the load on the rod bearings is higher. Unfortunately, any of these short stroke, nearly-square and over-square engines produce less torque and have to be set-up to run at higher RPM’s to produce their maximum power, which is limited by their increased crankshaft slip-bearing surface speeds. Unfortunately, as bearing surface speed increases, bearing wear increases and so does the risk of bearing failure, especially in the case of the narrow bearings used in the 8.2.

In the illustration above, the short stroke “oversquare” engine has a cylinder bore greater then the stroke (Example: 4″ bore and 2″ stroke). The “square” engine has a bore equal to the stroke (Example: 3″ bore and 3″ stroke). The long stroke “undersquare” engine has a bore smaller then the stroke (Example: 2″ bore and 6″ stroke). Some very light-duty diesel engines and most automotive gasoline engines are “square” or “oversquare” and therefore operate at higher RPMs and produce less torque then “undersquare” engines. Most diesel engines and heavy-duty gasoline engines are “undersquare” and run at lower RPMs, but can produce higher torque.

Shorter connecting rods can exert higher side loads on the pistons causing faster wear of the piston skirts, rings and cylinder bores.

In conclusion

The above comparisons show why smaller V8 engines that lack the space for the wider crankshaft bearings and stronger crank webs are not capable of the higher power outputs of comparable displacement inline engines. These are some of the main reasons why most engine manufacturers have abandoned building small V8 diesel engines for use in the more demanding applications such as marine service, and have embraced inline configurations especially the turbocharged 6 cylinder inline with 7 main bearings such as the Cummins B and C series engines. Consider this: None of the small V8 diesel engines, such as the Ford and GM pickup truck engines, have successfully achieved reliable service as marine propulsion engines.

1st Side Note: Small “V” configuration 2-stroke cycle engines such as Detroit Diesel V53 & V71 series engines experience much longer bearing service with slower wear then small “V” configuration 4-stroke cycle engines like the 8,2 mainly because the 2-stroke cycle design inherently produces lower vibration induced loading on the crankshaft bearings and more consistent loading of the bearings mainly because a 2-stroke cycle engine does not have an intake stroke.

2nd Side Note: Larger “V” configuration engines (V4, V6, V8, V12, V16,+) with larger cylinder bores have longer crankshafts and therefore have more room for wider crankshaft bearings and stronger crank webs, which means that they can have stronger “bottom ends” that allows them to produce higher power outputs per displacement unit then their smaller, shorter, and weaker little brothers.

Other 8.2 issues

Tuning-up the engine, especially adjusting the injectors, is complex, time consuming, and requires special tools which are becoming more and more scarce. One such tool is the Timing Pin and Guide Tool # J 29139 illustrated on SEC 14.2.1 page 1 of the Detroit Diesel 8.2L Service Manual #6SE421. This manual is available to current Academy members for viewing from our Academy eLibrary. The complete procedure is described in that section (14) of the manual including the special tools required. Several of these tools are no longer available from GM or Detroit Diesel, but most can be fabricated. It would be much more convenient to find someone knowledgeable and experienced in the procedure who already has the proper tools, but this is proving more difficult with each passing day. The above service manual also contains sections on Preventive Maintenance and Trouble Shooting that can be very helpful.

Quality replacement parts are becoming scarce and more expensive. New major parts (i.e. blocks, heads, crankshafts, etc.) are practically non-existent and usable used parts are also becoming scarce.

How to keep the 8.2 alive

Since the 8.2’s “Open Deck free-standing” cylinder design often results in head gasket crushing whenever the cylinder metal expands from increasing heat as explained earlier, one would be wise to reduce the times that the engine goes through temperature changes. For example, reduce through preplanning as much as practical, the number of cycles where the engine is started cold, warmed up to running temperature, shut off and allowed to cool down.

Since the 8.2’s “Open Deck free-standing” cylinder design often results in head gasket chaffing whenever the cylinder is forced to flex from side-to-side by heavy loading of the engine as explained earlier, one would be wise to reduce the load on the engine. For example, reduce the propeller pitch slightly to let the engine run more easily and never over-prop the boat.

Because of these recognized inherent weaknesses, Detroit Diesel never did set up the 8.2 engines to produce very high power outputs (see Engine Specifications Table later in this article). Fortunately, in a vehicular application, the engine is rarely operated at higher speed and power output for very long, usually just during acceleration and when climbing hills. If the 8.2 engine is intentionally operated at reduced power (below 80%), by shifting down and easing up on the throttle, doing so has proven to help it survive. This is why some truck operators have experienced few if any problems with their 8.2s. In a marine application this can be accomplished by under-pitching the propeller, avoiding any rapid acceleration, and if necessary, reducing the vessel’s cruising speed. Unfortunately, this will lower combustion gas temperatures (sometimes below 800ºF) which usually encourages more carbon buildup in the combustion chamber along with its ensuing problems, including “injector misfire” and detonation. Since the practice of routinely running at full throttle (flank speed) to blow out the carbon soot is NOT recommended with the 8.2, because doing so often results in head gasket failure or catastrophic bearing failure, other ways of reducing carbon buildup must be utilized. Unfortunately, the benefits of “water injection” are limited because the 8.2 should not be run at full throttle when most of the soot would be “steam-cleaned” and blown out. But adding fuel additives that help keep fuel injectors clean and reduce carbon buildup can be quite helpful.

Like many 4-Stroke Cycle engines, the 8.2 will tend to detonate when started in colder weather. Detonation is the phenomenon when the heated gases from combustion expand in the combustion chamber faster then the speed of sound and generate a supersonic shockwave. Detonation in a cold engine is the result of the increased ignition lag-time that unfortunately, delays ignition until the combustion chamber has an overabundance of fuel. Once ignited, the large quantity of fuel burns too fast, generating a shockwave. This shockwave or “sonic boom” if you like, can be heard by the naked ear as the characteristic “knock” or “ping” of detonation depending on the frequency of the sound, the “ping” being the higher frequency. Typically, the larger the cylinder, the lower the frequency. When detonation occurs in the 8.2, which mechanically injects the diesel fuel directly into the relatively fragile cylinder instead of into a heavily reinforced precombustion chamber, the shockwave too often causes damage to the already “weak” head gaskets because they are directly exposed to the shockwave. Starting any diesel engine, but especially an 8.2 in cold temperatures is greatly improved by fitting an engine warming device such as a block heater or an intake air heater. Heating the engine or the incoming air reduces the ignition lag-time, avoiding detonation before the engine warms up.

It is never a good idea to use “Ether” to start an 8.2 as it will often detonate in the cylinders causing head gasket damage or worse. Detroit Diesel made the mistake of providing a cold weather starting fluid injection canister as an option on the automotive and industrial versions of the 8.2, just like they had offered on their 2-Stroke Cycle engines which were not prone to detonation, giving the impression that spraying starting fluid into the 8.2 was acceptable. Of course it proved to be detrimental and many 8.2 engines have been seriously damaged as a result.

The starting fluid device was never offered for the marine version of the 8.2 because having such a volatile fuel as starting fluid in the engine space of a vessel, especially a diesel fueled one, is extremely dangerous. Why are volatile fuels such as starting fluid, gasoline or propane so dangerous in diesel powered vessels? Well remember that electrical devices such as relays, generators, alternators and starter motors on gasoline fueled inboard engines are required to be ignition protected, but most diesel inboard engines are not required to have electrical equipment designed with ignition protection and therefore can provide an ignition source such as a spark that can result in an explosion and fire in the engine space. Also, a diesel engine can “run away” on a volatile airborne fuel in the engine space. So instead of using starting fluid, if the temperature is too cold for the engine to start easily, it is better to fit an engine warming device such as a block heater which is usually AC powered and/or an intake air heater which is usually DC and can be powered by the ship’s batteries. Block heaters must be used with care as they warm up the whole engine block including the crankcase which includes the crankshaft and its bearings. Over time, the warm engine oil which is less viscous. will drain out of the bearings, leaving them dryer during the starting process, until the oil pump refills them with oil. If a block heater is used, it is best to install an engine pre-oiler discussed later in this article.

Next, pay particular attention to the engine’s cooling system, especially the raw water pickup and sea strainer. Keep them clear of any obstructions. Also keep the raw water pump impeller, the heat exchanger, the engine coolant (antifreeze), the pressure cap, all hoses, and the engine belts and pulleys in good shape. The exhaust mixing elbows on wet exhaust systems should be routinely checked for deterioration and clogging. Due to the poor design detailed above regarding head gasket failures, even the slightest overheating can result in serious consequences. Keep in mind that most 8.2 overheating events are caused by coolant loss from a leaking head gasket rather then the other way around. Therefore, any coolant loss should be investigated immediately to determine if it is due to a leaking head gasket, and if the engine has already suffered other damage such as from hydrolocking. If the coolant level has dropped during or after engine operation, the cause should be identified and cured before starting the engine to avoid hydrolocking.

Adding section on coolant return tank and pressure cap soon.

Test coolant for combustion gases.

Fluid analysis of the engine coolant and engine oil can help detect a leaking head gasket and can also help determine the extent of other internal damage.

It may also prove helpful to pull the fuel injectors and inspect the cylinders with a borescope for internal engine damage, and “water washing”, which is evidence of a “blown” head gasket.

If you replace injectors BEWARE. The injector markings may NOT indicate that the injectors have been drilled larger for the greater fuel delivery required by the higher rated engines. This can result in some or all of the injectors delivering too much fuel for the lower rated engines or too little fuel for the higher rated engines. Ensure that the injectors’ fuel discharge holes, valves, etc. are the proper size for the rated horsepower of the engine. And yes, your engine may have already suffered this injector mismatch.

Ensure that the engine oil is properly maintained. Always use a quality Diesel Engine Lubricating Oil such as DELO 400. DO NOT USE DELO 100 as it is a low detergent oil intended for Detroit Diesel’s 2-Stroke Cycle engines which do not suffer oil contamination from soot blowby. See our webpage on engine oil. Always shake or stir the new oil container to mix the new oil before pouring the new oil into the engine as the oil and additives tend to separate over time. This is especially true of larger containers of oil such as drums which must be stirred routinely to mix the heavier additives like zinc that tend to settle to the bottom of the drum. Always maintain the proper oil level in the engine. Always replace the oil filter during every oil change. Then cut open the old filter and check it for metal. See our webpage on Inspecting Oil Filters for metal. Always use a quality oil filter. Consider fitting the engine with a by-pass type oil filter in addition to the original full-flow oil filter. See our Article on Installing a Bypass Oil Filter. The small micron by-pass filter’s element can remove much smaller contaminate particles from the oil then the larger micron full-flow filter’s element can, thus reducing wear from oil contaminates. The 8.2’s narrow crankshaft bearings make them more susceptible to wear from these smaller particles contaminating the oil when the oil film between the bearing and crankshaft is pressed thin.

Lastly, let’s consider one more source of wear and failure. If the engine sits dormant for long periods, consider fitting a pre-oiler to the engine to pressurize the oil galleys and fill the bearings before starting the engine. This practice reduces wear during startup, which is considerable especially in the case of the narrow 8.2 crankshaft bearings. Pre-oilers are often fitted to commercial engines to reduce startup wear. See our webpage on Engine Pre-Oilers.

A surprising number of vessels were fitted with 8.2s for propulsion due to their rather reasonable price. Unfortunately, due to the 8.2’s shortcomings, many of these engines are in serious trouble. Some of the owners aren’t aware of any problems, but again some are. There is no denying that the 8.2’s problems haven’t adversely effected the value of the vessels which are equipped with them. Whether you own such a vessel already or are considering buying one, a good place to start is with a fluid analysis of a properly drawn engine oil sample. Even when you don’t have any previous sampling results to trend from, The analysis of a single current sample can still reveal if any of the shortcomings inherent in the 8.2 have already resulted in damage to the engine and to just what extent. Academy members have the opportunity to submit oil analysis reports to our engine experts (at no charge) for their opinions and suggestions as part of our “Ask An Expert” Program.

If the 8.2 is currently in good condition, and your plan is to keep the engine for awhile, the best advise is to make the above improvements, keep it maintained, and run it easy. If you intend on keeping the vessel for a while, you should probably start budgeting for a repower. But remember that tight quarters may limit your choice of replacement engines. When available, the somewhat larger Cat 3208 has been a popular repower option and of course has proven to be a much better engine. The Cummins “Triple-Nickel“, not so much. If the engine space is large enough, the Cummins “B” or “C” series which are inline engines have proven to be excellent choices. See our article Selecting the Right Diesel Engine for Your Boat.

What others have said about the 8.2